Heat-Shrink vs. Cold-Shrink Cable Accessories: A Comparative Guide

2025-09-19 17:23Cable terminations and splices are critical for ensuring the safety, reliability, and longevity of electrical systems. Heat-shrink and cold-shrink accessories are the two primary technologies used to achieve insulation, sealing, and environmental protection in cable joints and terminations. While both serve the same fundamental purpose, they differ significantly in installation methods, performance characteristics, and ideal applications.

1. How They Work

Heat-Shrink Accessories

These accessories are made from polymer materials (often polyolefin) that have been "pre-expanded" during manufacturing using radiation cross-linking. When heated with a propane torch or hot air gun, the material shrinks radially (typically at a 3:1 or 4:1 ratio) to form a tight, conformal seal around the cable. Many heat-shrink products also include a sealant layer that melts during heating to provide an environmental moisture barrier.

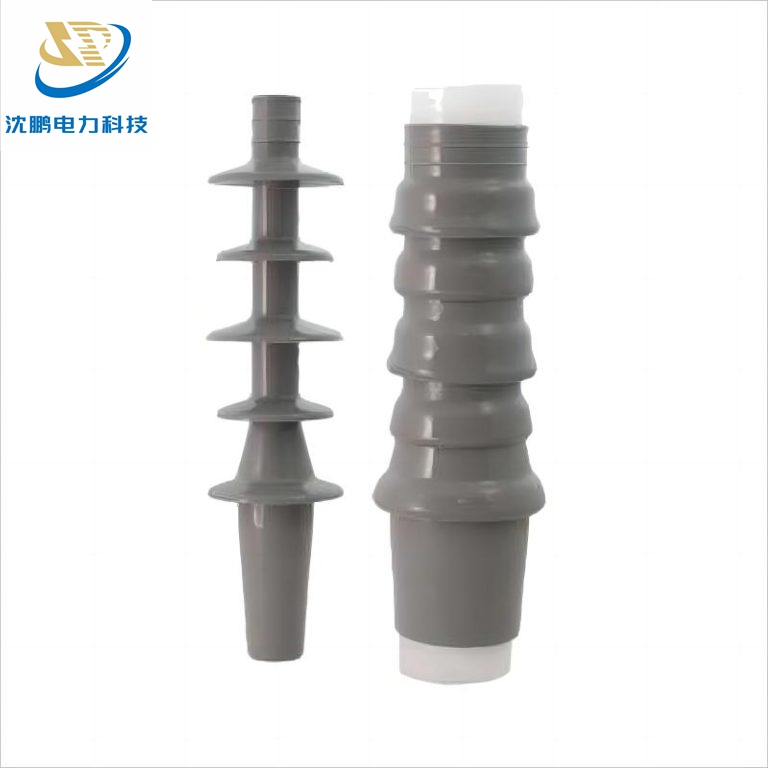

Cold-Shrink Accessories

Cold-shrink accessories are made from highly flexible silicone or EPDM rubber that is pre-expanded and held in place on a removable plastic support core. During installation, the core is pulled out (usually by hand), allowing the material to elastically contract onto the cable without any external heat source. This creates instant pressure and a reliable seal.

2. Key Differences

The primary distinction between these two technologies lies in their installation process and material behavior. Heat-shrink accessories require the application of an external heat source—such as a propane torch or hot air gun—to activate shrinkage. The polymer material contracts radially when heated, forming a tight seal around the cable. This process demands skill and care to ensure even heating and avoid damage.

In contrast, cold-shrink accessories utilize pre-expanded rubber components held in place by a removable plastic support core. Installation is achieved simply by pulling out this core, allowing the material to elastically contract onto the cable without any heat. This makes the process faster, safer, and less dependent on installer skill.

Another critical difference is the final characteristic of the installed accessory. Heat-shrink materials, typically polyolefin-based, become rigid after cooling, forming a strong but inflexible seal. Cold-shrink accessories, usually made from silicone or EPDM rubber, remain highly flexible even after installation. This inherent flexibility makes cold-shrink superior for applications subject to vibration, thermal cycling, or minor cable movement.

Furthermore, the two technologies differ significantly in their suitability for various environments. Heat-shrink installation involves open flames or high temperatures, making it unsuitable for hazardous or explosive atmospheres. Cold-shrink, being a flame-free process, is ideal for such dangerous locations. Cold-shrink accessories also generally offer better resistance to extreme temperatures, UV radiation, and environmental weathering due to their silicone rubber construction, often providing a wider operational temperature range and longer service life in harsh outdoor conditions.

3. Application Fields

Heat-Shrink is Typically Used For:

Industrial plants and indoor substations where heat application is safe.

Fixed installations with minimal movement or vibration.

Budget-sensitive projects where material cost is a primary concern.

HV and MV terminations in dry, accessible environments.

Cold-Shrink is Preferred For:

Explosive or flammable environments (e.g., chemical plants, mines) where open flames are prohibited.

Confined or hard-to-reach spaces (e.g., underground joints, cable tunnels).

Applications requiring flexibility (e.g., wind turbine nacelles, vibrating machinery).

Critical installations where speed, safety, and reliability are prioritized over cost.

Outdoor and submersible applications due to superior environmental sealing and UV/ozone resistance.