Thermocouple Extension and Compensating Wires: Extending the Reach of Temperature Sensing

2026-01-07 16:20In industrial temperature measurement, thermocouples reign supreme for their wide range, robustness, and speed. However, a fundamental challenge arises: the temperature-sensitive junction must be at the measurement point (e.g., inside a furnace), while the expensive and sensitive measuring instrument (transmitter, PLC) must be located in a safe, controlled environment, often many meters away. Connecting them directly with ordinary copper wire would introduce new, unintended thermoelectric junctions, creating massive measurement errors. This is where Thermocouple Extension and Compensating Wires come in--specialized cables designed to accurately and cost-effectively transmit the millivolt signal from the thermocouple to the readout device without distorting it.

The Core Science: Preserving the Thermoelectric EMF

The principle is based on the Seebeck effect: a thermocouple generates a tiny voltage (EMF) based on the temperature difference between its hot junction (measurement point) and its cold junction (reference point, typically at the instrument). The key function of extension/compensating wire is to move the effective cold junction from the thermocouple head to the instrument terminals.

Ideal Wire: In a perfect world, the extension wire would be made of the exact same metals as the thermocouple itself (e.g., Chromel and Alumel for Type K). This is called Extension Grade wire. It is essentially a seamless, longer version of the thermocouple.

Practical & Economic Wire: For the most common thermocouple types (like K, J, T, E), making very long cables from the exact, often expensive, thermocouple alloys is cost-prohibitive. Compensating Grade wire is used instead. It is made from different, cheaper metals (e.g., copper and a copper-nickel alloy) that are carefully engineered to mimic the thermoelectric properties of the true thermocouple metals only over a limited, lower temperature range (typically 0-200°C).

Key Definitions: Extension vs. Compensating Wire

This critical distinction is based on materials and application:

Extension Wire: Has conductors of the same nominal composition as the thermocouple pair (e.g., Type KX wire uses Chromel and Alumel). It can be used over the full temperature range of the thermocouple and is typically used in the hottest zone closest to the sensor. It is more expensive.

Compensating Wire: Has conductors of different composition that produce a similar EMF-to-temperature relationship as the thermocouple, but only at lower ambient temperatures. It is designed for the ambient temperature zone between the thermocouple head and the instrument. It is more economical for long runs.

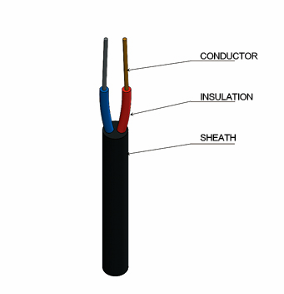

Anatomy of the Cable: More Than Just Two Wires

A proper thermocouple cable is a carefully assembled system:

Conductor Pair: The two insulated wires, each made of the specific alloy for the thermocouple type (K, J, T, etc.). Polarity is critical and is enforced by color-coding (internationally standardized: e.g., Type K positive is green, negative is white per IEC 60584-3).

Individual Insulation: Color-coded PVC, PTFE (Teflon), or Fiberglass, chosen for temperature rating and chemical resistance.

Overall Shield: A braided copper or aluminum foil shield is often included to protect the delicate millivolt signal from electromagnetic interference (EMI) generated by motors, drives, and power lines.

Outer Jacket: Provides mechanical protection. Common materials include PVC, PUR (for oil/flex resistance), or FEP (for high heat and chemical resistance).

Selection and Installation: Ensuring Accuracy

Choosing the correct wire is paramount for measurement integrity:

Match the Thermocouple Type: A Type K thermocouple must use Type KX (extension) or Type KC (compensating) wire. Mixing types guarantees large, unpredictable errors.

Understand Temperature Zones: Use extension grade for any part of the run exposed to high temperatures (e.g., near the furnace). Use compensating grade for long runs through cable trays in ambient plant conditions.

Respect Temperature Limits: Never expose compensating wire to temperatures near the process measurement point. Its calibrated mimicry fails at higher temperatures, introducing error.

Polarity & Connections: Ensure correct polarity (positive to positive) at all connection points (head, junction boxes, instrument). Use dedicated thermocouple connectors or terminal blocks to avoid creating parasitic junctions with dissimilar metals.

Shielding & Routing: In electrically noisy environments, always use shielded cable and route it away from power cables, preferably in separate trays or conduits.

Common Applications: Where Precision is Paramount

These wires are ubiquitous in process industries:

Petrochemical & Refining: Connecting furnace, reactor, and distillation column thermocouples to control rooms hundreds of meters away.

Power Generation: Extending signals from boiler, turbine, and steam line sensors.

Pharmaceutical & Food Processing: In hygienic environments where instruments are located outside cleanrooms or wash-down areas.

Plastics & Semiconductor Manufacturing: For precise temperature control of extruders, molds, and diffusion furnaces.

Thermocouple extension and compensating wires are not mere electrical conductors; they are calibrated components of the temperature measurement system itself. A failure in their selection or installation—a mismatched type, reversed polarity, or overheating—directly translates to a faulty temperature reading, which can lead to poor product quality, energy waste, or even safety incidents. By understanding their science, respecting the distinction between extension and compensating grades, and following rigorous installation practices, engineers ensure that the valuable data generated at the hot junction is delivered faithfully to the controller, maintaining the integrity of the entire process control loop.