What is the difference between rubber and PVC cable?

2025-12-23 16:22When selecting a cable for any application, one of the most fundamental decisions is the material of its outer sheath and insulation. Two of the most common contenders are Polyvinyl Chloride (PVC) and various forms of Rubber (typically EPR, CSPE, or Silicone). This isn't merely a cosmetic or cost choice; it's a decision that determines the cable's flexibility, durability, environmental resistance, and safety profile. Understanding the core differences between rubber and PVC cables is essential for specifying the right product to ensure longevity and reliability.

The Core Difference: Thermoplastic vs. Thermoset

The most fundamental distinction lies in their molecular behavior when heated.

PVC is a Thermoplastic: This means it softens when heated and hardens when cooled, a process that is reversible. This property makes it easy to manufacture and recycle but imposes limits on its high-temperature performance.

Rubber (EPR, Silicone) is a Thermoset: During a curing process (often using heat or radiation), the polymer chains form permanent, cross-linked bonds. Once set, a thermoset material will not melt or flow when reheated; it will ultimately char and degrade at very high temperatures. This structure gives it inherent stability under thermal and mechanical stress.

Head-to-Head: A Property Comparison

| Property | PVC Cable | Rubber Cable |

| Flexibility & Elasticity | Stiffer, especially in cold temperatures. Can become brittle over time as plasticizers migrate. | Excellent, elastic flexibility even at low temperatures. Maintains shape after bending/twisting. |

| Temperature Range | Standard: -5°C to +70°C. Special grades up to 105°C. Softens at lower high temps. | Wider range. Standard EPR: -40°C to +90°C. Silicone: -60°C to +180°C+. |

| Environmental Resistance | Good resistance to water, acids, and alkalis. Poor resistance to oils, fuels, ozone, and UV (unless specially formulated). | Superior overall. Excellent resistance to oils, fuels, ozone, UV, and chemicals. Ideal for harsh conditions. |

| Flame Retardancy | Naturally flame-retardant due to chlorine content. | Often requires additives to achieve similar flame retardancy. Special grades (like CSPE) are excellent. |

| Smoke & Toxicity | Produces thick, black, toxic, and corrosive smoke (HCl gas) when burned. A major safety concern in confined spaces. | Halogen-free options (many elastomers) produce less smoke, and it is non-corrosive. |

| Abrasion & Tear Resistance | Good, but can be cut or nicked. | Generally superior, with a tougher, more resilient jacket. |

| Cost & Weight | Lower cost and lighter weight. | Higher cost and often heavier. |

The Ideal Domains: Where Each Material Excels

Choose PVC Cable When:

Cost is a primary driver for fixed installations.

The environment is dry, indoor, and stable (e.g., behind walls, in conduits, office buildings).

The application is for general-purpose wiring, house wiring, or low-flex control panels.

There are no significant exposure risks to oils, chemicals, or extreme temperatures.

Choose Rubber Cable When:

The cable will face constant flexing, bending, or movement (e.g., on cable reels, robotic arms, mining machinery, stage equipment).

The environment is harsh: outdoors, in industrial plants, exposed to oils, solvents, ozone, or wide temperature swings.

Low-temperature flexibility is required (e.g., cold storage, outdoor winter applications).

Enhanced safety for confined spaces (like ships, trains, tunnels) demands low-smoke, halogen-free performance.

The application is for heavy-duty tools, welding cables, or portable power supply.

The choice between rubber and PVC is not about which material is "better," but which is appropriate for the operating environment and mechanical demands.

PVC is the economical, reliable workhorse for standard, fixed installations where harsh conditions are not a factor. Think of it as the standard "utility" option.

Rubber is the durable, flexible specialist built to survive physical abuse, chemical exposure, and demanding thermal cycles. Think of it as the heavy-duty "industrial" or "mobile" option.

Specifying the wrong material can lead to premature cable failure—cracking, hardening, softening, or insulation breakdown—resulting in downtime, safety hazards, and higher replacement costs. By matching the cable's material to its real-world operating life, you ensure a safe, reliable, and cost-effective installation.

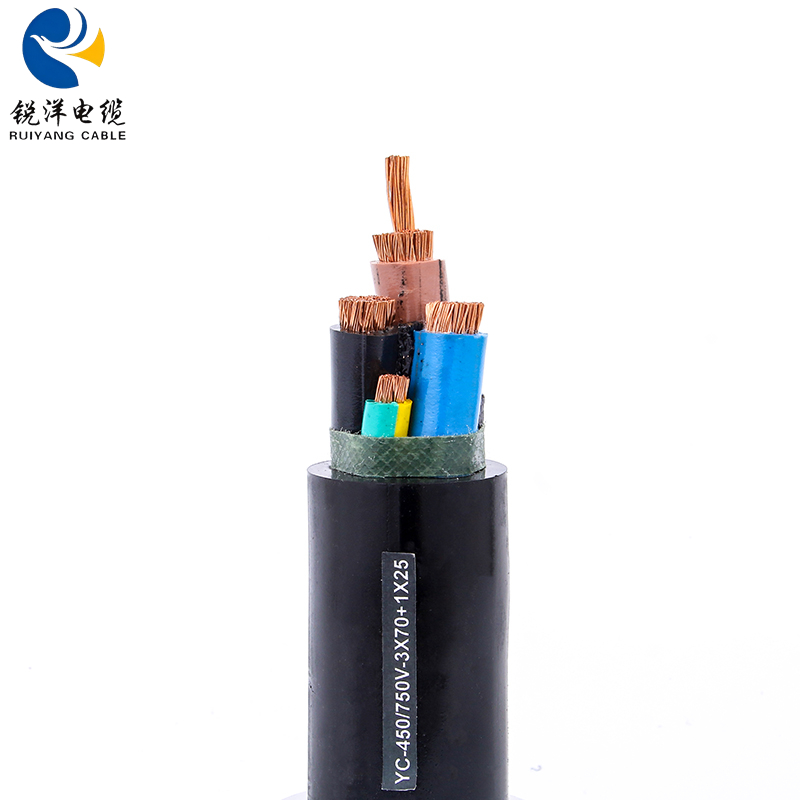

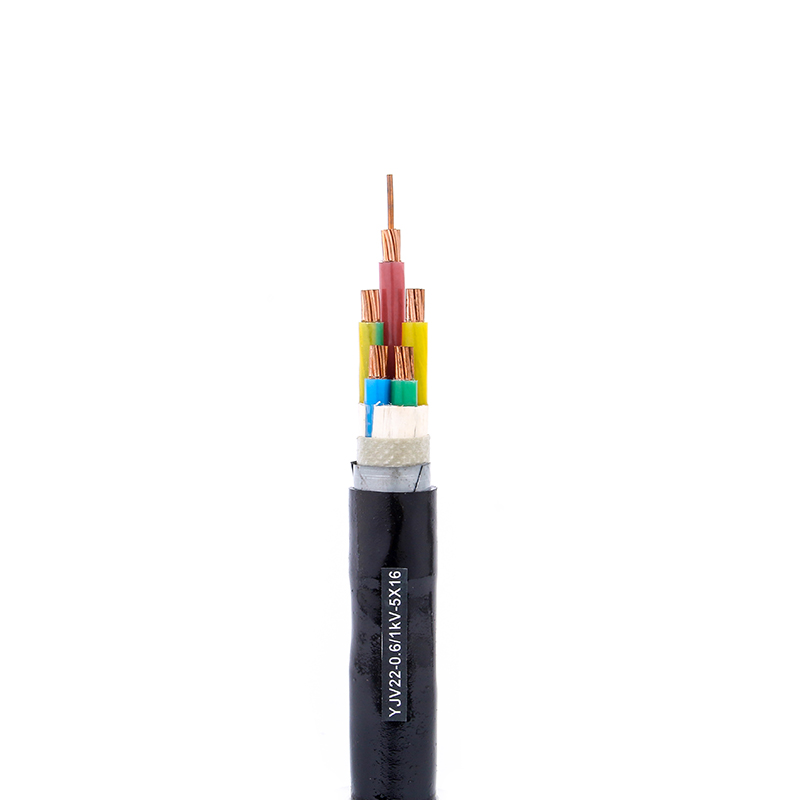

>>> Ruiyang Group's main Rubber-Sheathed Cable