- Home

- >

- Products

- >

- Airfield Cable

- >

Airfield Cable

Airfield Cable

Certification: ISO9001/ISO14001/OHSAS18001/CCC

ODM&OEM: Yes

Transport Package: Wooden drum, iron wooden drum or according to your requirements

- Ruiyang Group

- Shenyang, China

- 15 working days after payment is received

- 5000 kilometers per week

- Information

- Download

Airfield Cable

Product Description

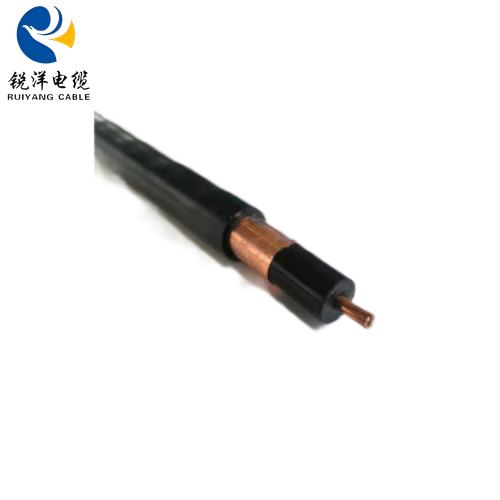

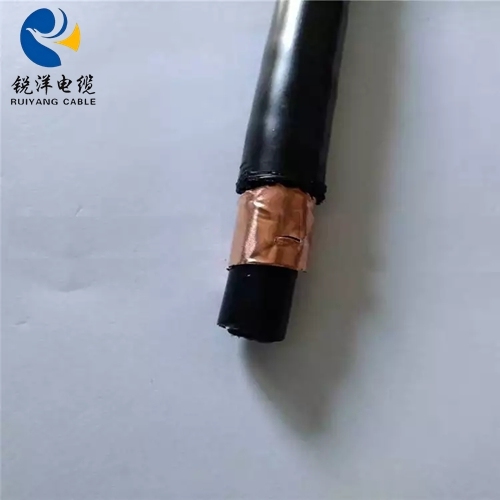

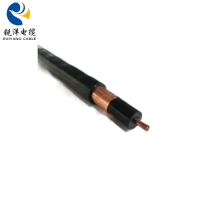

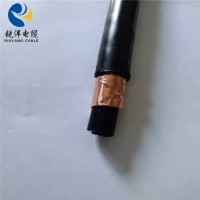

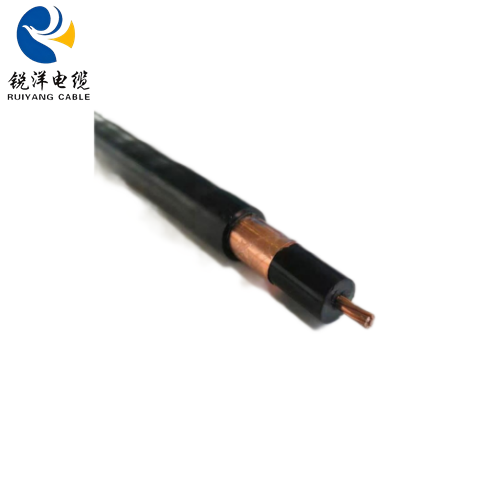

Airfield Cable is a highly specialized type of electrical cable engineered for the demanding environments of aviation infrastructure, particularly in runway, taxiway, and apron areas. Designed to power critical airfield ground lighting (AGL) systems-such as runway edge lights, approach lights, and signage—this cable boasts exceptional durability against mechanical stress, jet fuel exposure, moisture, temperature extremes, and UV radiation. Its construction typically features multiple layers of protection, including reinforced armor, chemical-resistant insulation (e.g., XLPE or EPR), and a robust outer jacket (often PVC or polyurethane), ensuring reliable power transmission and signal integrity under heavy loads and harsh conditions. The cable is engineered for direct burial or duct installation, complying with stringent international aviation standards to maintain operational safety and continuity.

Ideal for military and civilian airports, helipads, and airbase projects, Airfield Cable prioritizes safety and longevity. The cable's design also accommodates constant exposure to aviation fuels, de-icing fluids, and hydraulic oils, preventing degradation and maintaining performance over decades. This cable is a critical component in ensuring uninterrupted navigation and lighting systems for aircraft ground operations.

Detailed information:

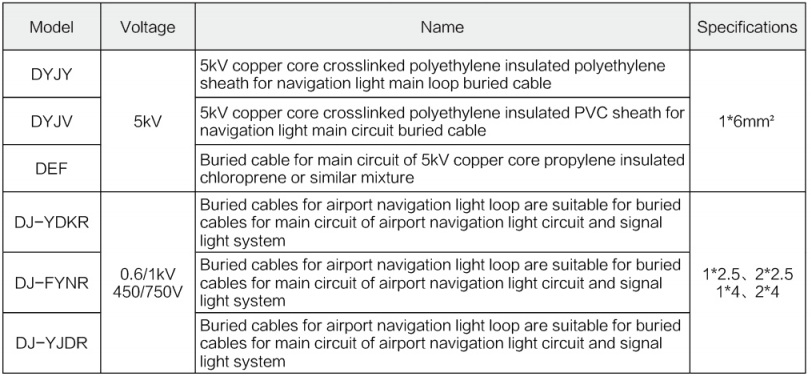

Type & Model

Rated Voltage

The rated voltage of the cable is 450/750V ,0.6/1 (1.2) kV and 5kV.

Execution Standards

MH/ T 6049-2020 Buried cables for airport navigation light loop.

Q / RYDL 014-2020 Extruded insulated airport navigation aid light secondary cable with rated voltage of 0.6/1kV and below.

Material Description

Conductor material: copper;

Conductor shielding: conductor with peroxide cross-linked semi-conductive shielding material PYJD;

Insulation materials: crosslinked polyethylene insulation, ethylene propylene rubber insulation mixture, crosslinked polyolefin insulation;

Insulation shield: insulation with peroxide crosslinking type can peel off the semi-conductive shield material PYJBJ;

Metal shielding layer: soft copper strip;

Lining layer: PPD embossing belt, PP belt, non-woven fabric, glass fiber band;

Isolation sleeve: polyvinyl chloride, polyethylene, polyolefin, silicone rubber, ethylene propylene rubber / elastomer;

Sheath: PVC, polyethylene, chloroprene or similar mixture sheath.

Technical parameters

① Conductor temperature during short circuit: cable short circuit allowable maximum temperature (maximum time 5S): ethylene propylene rubber, cross linked polyethylene insulated cable 250℃;

② Conductor operating temperature: ethylene propylene rubber, cross-linked polyethylene insulated cable 90℃;

③ Power frequency withstand voltage time and voltage: the power frequency voltage test is: 450 / 750 3kV/5min

0.6/1kV 3.5kV/5min;

5kV18kV/5min.

Company profile

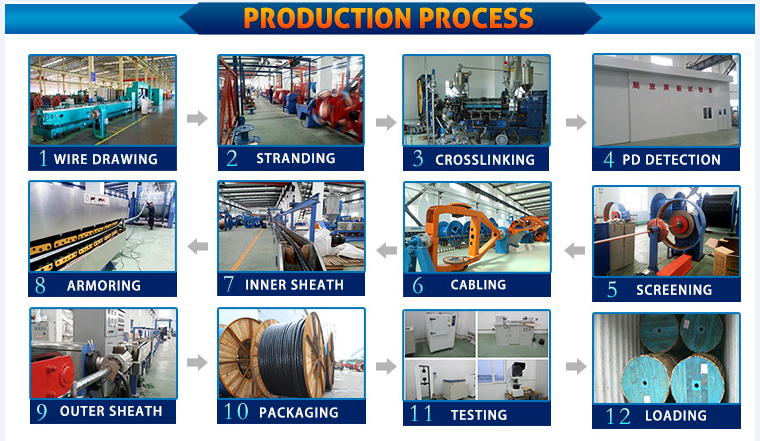

Production process

Applications

Product packaging

Our Services

1. Quickly and professional response.

2. China manufacturer with 8 years experience.

3. Excellent quality with reasonable price.

4. Sufficient support for our tendering representatives.

5. OEM service available based on official & legal authorization.

6. Strict quality control system.

7. Faster lead time than our competitors.

8. Cable solutions to your particular requirements.

9. Free sample is available with economic express fee.

10. 12 months quality guarantee after delivery.

Served Customers

FAQ

Q1: What kind of guarantee do you provide?

A1: 1. 100% high quality, all failed parts get free warranty within 30 days after received.

2. Accept 10 years warranty upon customer requirement.

3. Repairs parts are available within 10years; We will inform the EOL products to you from time to time.

Q2: What if the cable which we need have some differences on specifications from yours?

A2: Any difference, we can design and produce according to your requests, which include cable, color, material, processing requirement etc.

Q3: How can I get a sample to check your quality?

A3: After price confirmation, you can require for sample to check our quality. Sample is free, but the freight charge should be paid.