Connect Wire Sheathed Flexible Cable RVVP

Connect Wire Sheathed Flexible Cable RVVP

100m/Roll

Different colors

Certification: ISO9001/ISO14001 /OHSAS18001/CCC

ODM&OEM: Yes

Transport Package: Roll or according to your requirements

- Ruiyang Group

- Shenyang, China

- 15 working days after payment is received

- 5000 kilometers per week

- Information

- Download

Connect Wire Sheathed Flexible Cable RVVP

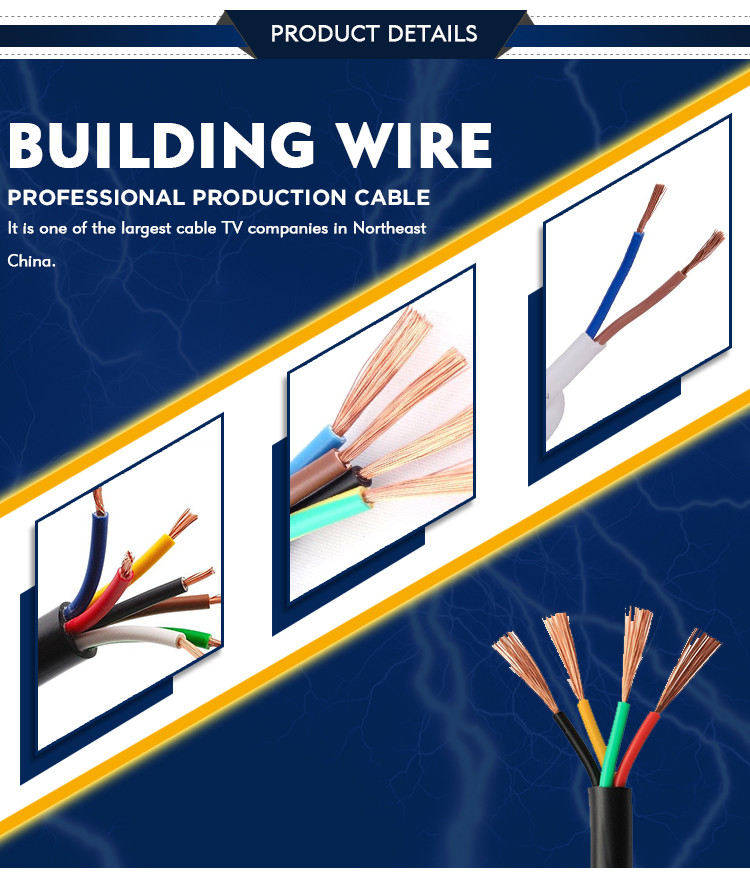

Product Description

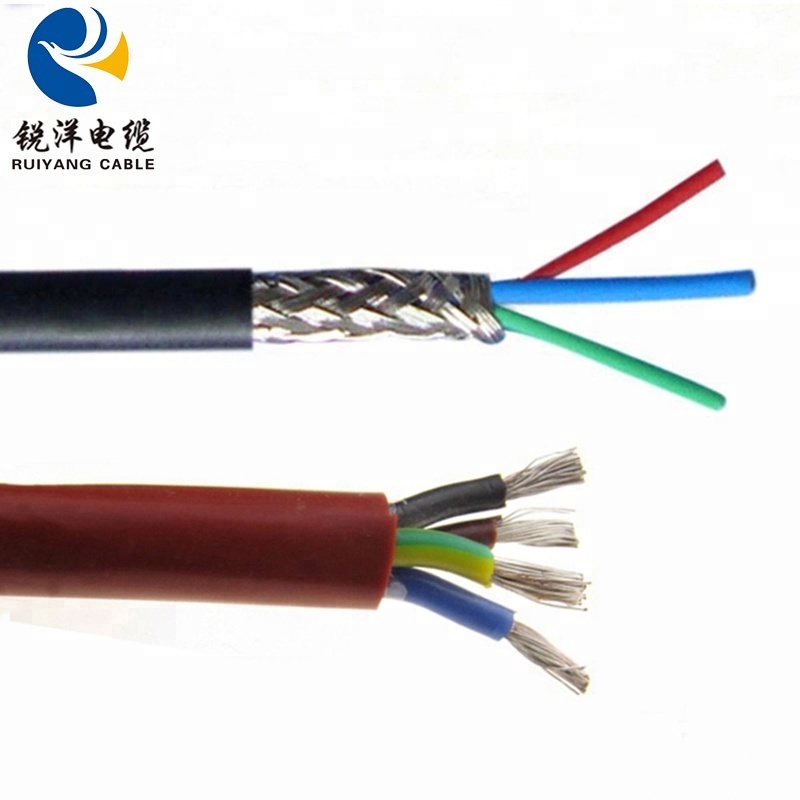

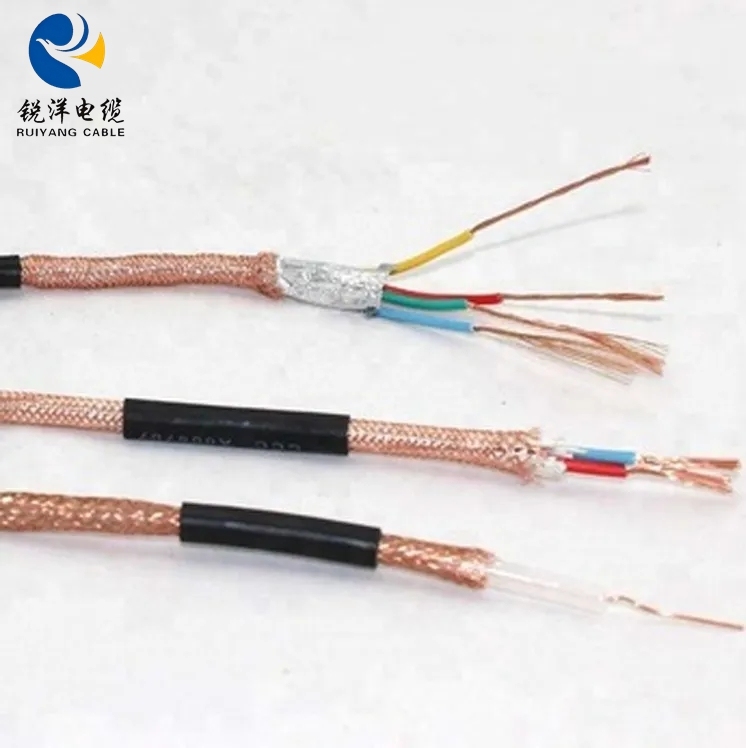

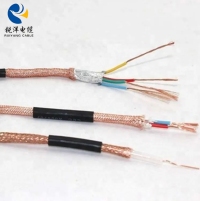

RVVP Cable is a specialized class of flexible shielded cable engineered to deliver reliable signal and power transmission in electromagnetically active environments where standard flexible cables would suffer performance degradation. This cable integrates finely stranded tinned copper conductors, each insulated with durable PVC, within a comprehensive shielding system featuring a high-coverage tinned copper braid that provides continuous electromagnetic protection. The entire assembly is encased within a flexible PVC outer sheath that maintains excellent mechanical resilience while allowing convenient handling and routing. Designed with a voltage rating of 300/500V, the RVVP cable combines the installation advantages of flexible wiring with the noise immunity of professional shielding technology, making it an essential solution for applications requiring both mobility and signal integrity in the presence of electrical interference.

The technical distinction of the RVVP cable lies in its integrated shielding architecture, which employs a densely woven tinned copper braid to create an effective Faraday cage around the internal conductors. The tinned construction of the braid enhances corrosion resistance and ensures reliable solderability for grounding terminations. Internally, the finely stranded conductors are optimized for repeated flexing without work hardening, while the PVC materials are selected for stable dielectric performance and resistance to abrasion, oils, and mild chemicals. This balanced design enables the RVVP cable to maintain low surface transfer impedance, effectively isolating sensitive circuits from external noise sources such as variable-speed drives, wireless transmitters, and switching power supplies, without sacrificing the flexibility required for dynamic or semi-permanent installations.

Use characteristics

1. If the finished insulation core and finished power line are immersed in warm water at 20±5 °C for one hour, they shall withstand the specified AC 50 Hz immersion voltage test.

2. The wire demonstrates excellent electrical insulation properties, mechanical strength, and flame retardancy, ensuring safety and reliability during use. The producer’s name, model, and rated voltage must be clearly marked on the surface of the finished power line, in compliance with insulation and sheath delivery requirements.

Related products

| Model | Name | Voltage(V) | Nominal section(mm2) | Number/diameter of core (mm) |

| RV | Copper core PVC insulation jointed flexible line | 300/500 | 0.3 to 1.0 | 16/0.15 to 32/0.2 |

| 300/500 | 1.5 to 10 | 30/0.25 to 80/0.30 | ||

| RVB | Copper core PVC insulation paralled jonted flexible line | 300/300 | 2×0.3 to 2×1.0 | 2×16/0.15 to 2×32/0.20 |

| RVS | Copper core PVC insulation twisted joint flexible line | 300/300 | 2×0.3 to 2×0.75 | 2×16/0.15 to 2×32/0.15 |

| RVV | Copper core PVC insulation sheath paralled joint flexible line | 300/500 | 2×0.75 to 5×2.5 | 2×24/0.2 to 5×49/0.25 |

| RVVB | Copper core PVC insulation sheath paralled joint flexible line | 300/300 | 2×0.5 to 2×0.75 | 2×16/0.2 to 2×24/0.2 |

| RV-105 | Copper core heat-resistance 105 PVC insulation joint flexible line | 450/750 | 0.5 to 6 | 16/0.2 to 84/0.30 |

Company profile

Applications

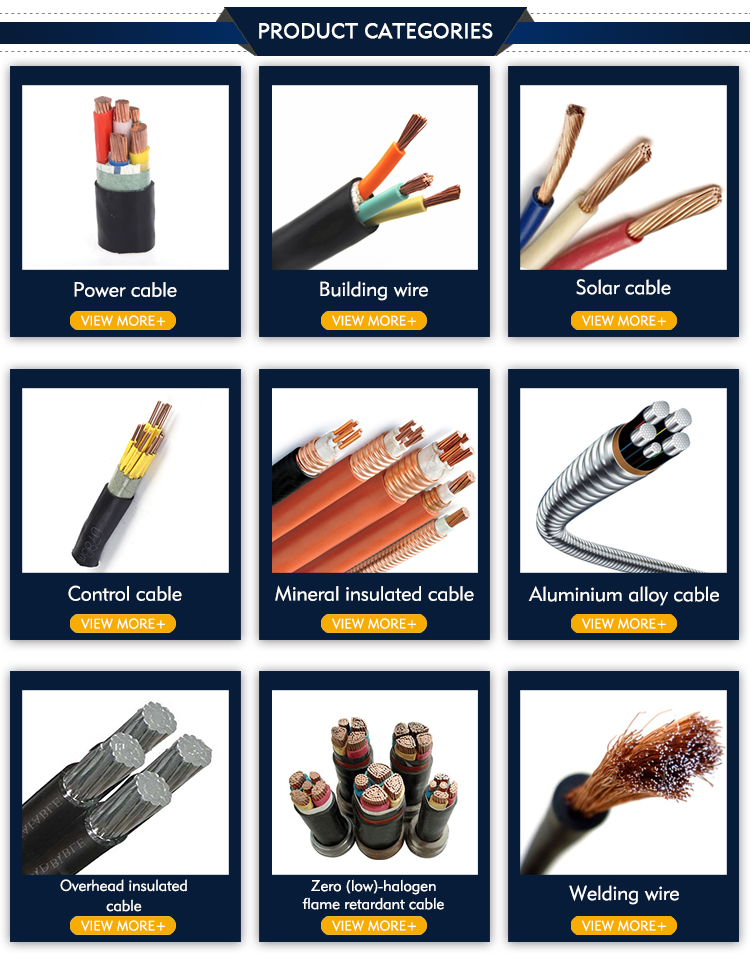

Product categories

Production process

Product packaging

Our Services

1. Quickly and professional response.

2. China manufacturer with 8 years experience.

3. Excellent quality with reasonable price.

4. Sufficient support for our tendering representatives.

5. OEM service available based on official & legal authorization.

6. Strict quality control system.

7. Faster lead time than our competitors.

8. Cable solutions to your particular requirements.

9. Free sample is available with economic express fee.

10. 12 months quality guarantee after delivery.

Served Customers

FAQ

Q1: What kind of guarantee do you provide?

A1: 1. 100% high quality, all failed parts get free warranty within 30 days after received.

2. Accept 10 years warranty upon customer requirement.

3. Repairs parts are available within 10years; We will inform the EOL products to you from time to time.

Q2: What if the cable which we need have some differences on specifications from yours?

A2: Any difference, we can design and produce according to your requests, which include cable, color, material, processing requirement etc.

Q3: How can I get a sample to check your quality?

A3: After price confirmation, you can require for sample to check our quality. Sample is free, but the freight charge should be paid.