Electrical Stress Control Self-adhesive Tape

Transport Package: Carton

OEM Order: Acceptable

Strict quality control system

- Shenpeng

- Shenyang, China

- 15 working days after payment is received

- 50000 pieces per month

- Information

- Download

Electrical Stress Control Self-adhesive Tape

Product Description

Electrical Stress Control Self-adhesive Tape represents an advanced engineering material specifically developed to address one of the most critical challenges in high-voltage cable systems: uncontrolled electric field concentrations. Unlike conventional insulating materials, this electrical tape functions as a field-grading medium, engineered with precisely calibrated electrical properties to transform dangerous point discharges into smooth, controlled potential gradients. Composed of a semi-conductive polymer matrix—typically ethylene-vinyl acetate (EVA) or synthetic rubber loaded with controlled carbon dispersion—and enhanced with a uniformly conductive pressure-sensitive adhesive layer, this electrical tape creates a seamless electrical interface that actively modifies field distribution. Its fundamental purpose is to eliminate the intense electrical stress that naturally occurs at discontinuities in cable shielding, particularly at termination points and joint interfaces where insulation shielding has been removed, thereby preventing the inception of destructive partial discharge activity.

This stress control tape serves as an indispensable component in constructing reliable high-voltage cable systems, finding essential application in numerous critical scenarios. Its primary function is in the fabrication of field-assembled cable terminations and joints for medium and high-voltage networks, where it is systematically applied over the cut-back region of the insulation screen to reconstruct a continuous, smooth electrical transition. The tape is equally vital in retrofit repairs and splice reinforcements on aging cable systems, where it can restore proper field distribution without requiring complete accessory replacement. For utility engineers and cable specialists working on grid interconnections, industrial power feeds, or renewable energy collector systems, this tape provides a field-proven method to ensure termination integrity. Its cold-application capability—requiring no heat sources or specialized tooling—allows for precise installation even in confined spaces or adverse weather conditions, making it a versatile solution for both planned installations and emergency repairs that demand immediate, reliable stress control to safeguard system integrity and operational continuity.

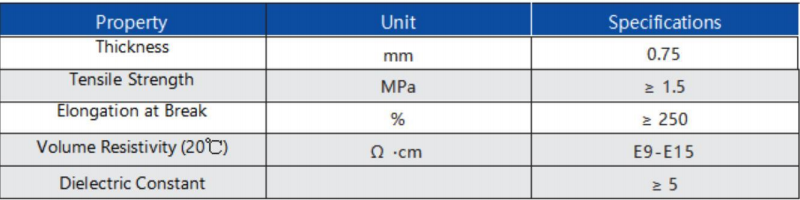

Specification Model

DYL-50

Product Dimensions

0.6*25*5000 (T×W×L)

Product Application

Used for stress control at cable joints and terminals, which can evenly distribute the electric field and reduce partial discharge. It is mainly used for bus - bar tubes and wrapped - type cable accessories (the wrapped - type is mainly for the overseas market). It is also applied in110kV/220kV intermediate joints in China.

Product Advantages

Electric Field Optimization: The high dielectric constant characteristic makes the electric field more uniform.

Good Flexibility: It can be used in a wide temperature range from -40℃ to 90℃, ensuring the stability of stress control effects.

Strong Durability: Less likely to experience performance degradation, cracking, or deformation.

Good Compatibility: It will not chemically react with or corrode the cable body.