- Home

- >

- Products

- >

- Reeling Cable

- >

Reeling Cable

Reeling Cable

Certification: ISO9001/ISO14001/OHSAS18001/CCC

ODM&OEM: Yes

Transport Package: Wooden drum, iron wooden drum or according to your requirements

- Ruiyang Group

- Shenyang, China

- 15 working days after payment is received

- 5000 kilometers per week

- Information

- Download

Reeling Cable

Product Description

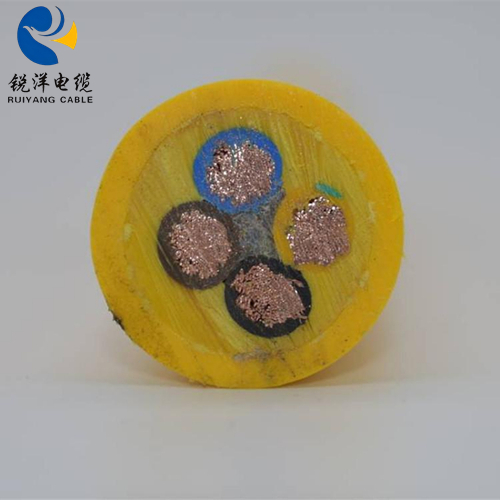

Reeling Cable is a specialized type of flexible cable engineered for continuous deployment and retraction on cable reels, winches, and automated winding systems. Designed to withstand constant mechanical stress from repeated bending and rolling, it features finely stranded conductors, advanced elastomeric insulation, and a robust yet flexible jacket—often polyurethane (PUR) or thermoplastic elastomer (TPE). This construction ensures exceptional resistance to abrasion, twisting, oils, and harsh environmental conditions, making it ideal for dynamic applications where cables are in continuous motion.

Widely used in industrial machinery, port cranes, mining equipment, and automated production lines, Reeling Cable maintains stable electrical performance under frequent movement. Its high-flex design prevents conductor fatigue, while specialized jacket compounds resist notch propagation and external impacts. Available in power, control, and hybrid versions (combining power and data transmission), the cable supports voltages up to 1kV and complies with international standards.

Detailed information:

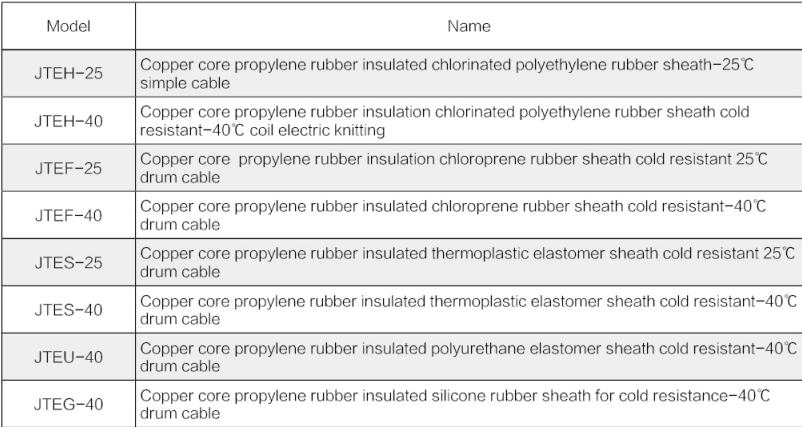

Type & Model

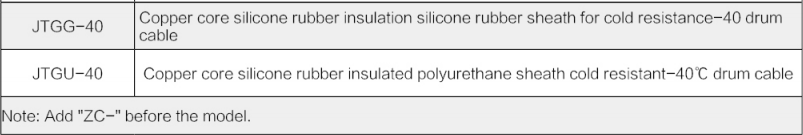

Specifications

Rated Voltage

The rated voltage of the cable is 0.6/ 1 (1.2) kV.

Material Description

Conductor material: copper;

Insulation materials: ethylene propylene rubber or synthetic elastomer insulation; silicone rubber mixture or synthetic elastomer insulation;

Sheath: polyurethane elastomer sheath; chlorinated polyethylene rubber mixture or synthetic elastomer sheath;Neoprene rubber mixture or synthetic elastomer sheath; silicone rubber mixture or synthetic elastomer sheath; other thermoplastic elastomer sheath.

Technical parameters

①Conductor temperature during short circuit: allowable maximum temperature (maximum time5S):250℃ for EPrubber: 350C for silicone rubber mixture or synthetic elastomer;

②Conductor operating temperature: EPDM insulation: 90℃; 180℃insulation for silastic mixture or synthetic elastomer

③ Power frequency withstand voltage time and voltage: the power frequency voltage test is: 0.6/1kV 3.5kV/5min.

Company profile

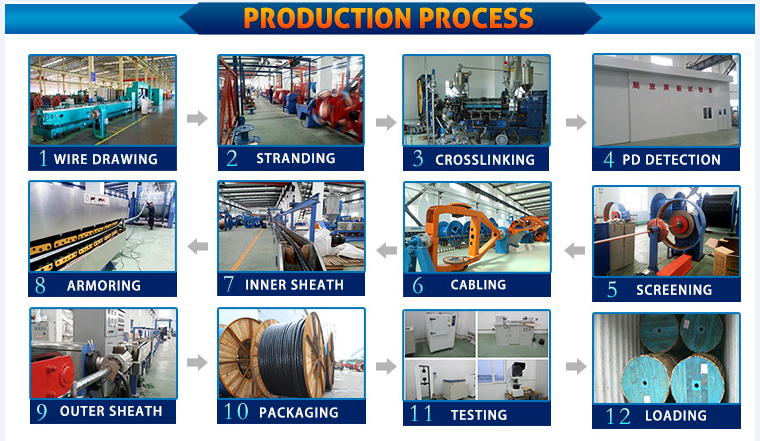

Production process

Applications

Product packaging

Our Services

1. Quickly and professional response.

2. China manufacturer with 8 years experience.

3. Excellent quality with reasonable price.

4. Sufficient support for our tendering representatives.

5. OEM service available based on official & legal authorization.

6. Strict quality control system.

7. Faster lead time than our competitors.

8. Cable solutions to your particular requirements.

9. Free sample is available with economic express fee.

10. 12 months quality guarantee after delivery.

Served Customers

FAQ

Q1: What kind of guarantee do you provide?

A1: 1. 100% high quality, all failed parts get free warranty within 30 days after received.

2. Accept 10 years warranty upon customer requirement.

3. Repairs parts are available within 10years; We will inform the EOL products to you from time to time.

Q2: What if the cable which we need have some differences on specifications from yours?

A2: Any difference, we can design and produce according to your requests, which include cable, color, material, processing requirement etc.

Q3: How can I get a sample to check your quality?

A3: After price confirmation, you can require for sample to check our quality. Sample is free, but the freight charge should be paid.