VFD Cable

Variable Frequency Drive Cable

Certification: ISO9001/ISO14001/OHSAS18001/CCC

ODM&OEM: Yes

Transport Package: Wooden drum, iron wooden drum or according to your requirements

- Ruiyang Group

- Shenyang, China

- 15 working days after payment is received

- 5000 kilometers per week

- Information

- Download

VFD Cable

Product Description

The VFD Cable is a specialized cable engineered specifically for use with Variable Frequency Drives (VFDs) to power electric motors in industrial automation systems. Unlike standard power cables, it is designed to withstand the unique challenges posed by VFDs, which output high-frequency Pulse Width Modulated (PWM) signals. These signals can cause voltage spikes, reflected wave phenomena, and significant electromagnetic interference (EMI). The cable's construction typically features symmetrical, parallel cabled conductors to minimize inductive imbalance, specialized insulation resistant to partial discharge, and robust multi-layer shielding—often a combination of a drain wire, aluminum foil, and a tinned copper braid. This design ensures reliable motor operation, protects against premature insulation failure, and contains EMI to prevent disruption to sensitive nearby equipment.

Ideal for harsh industrial environments like manufacturing plants, processing facilities, and HVAC systems, the VFD Cable enhances system longevity and reduces downtime. Its advanced shielding effectiveness suppresses both radiated and conducted noise, ensuring compliance with EMC regulations. The cable is built for durability, with oil-resistant and flexible jackets that can withstand mechanical stress, temperature variations, and exposure to chemicals. By providing a clean power transmission path from the drive to the motor, it is an essential component for maximizing the performance and lifespan of the entire variable speed drive system.

Detailed information:

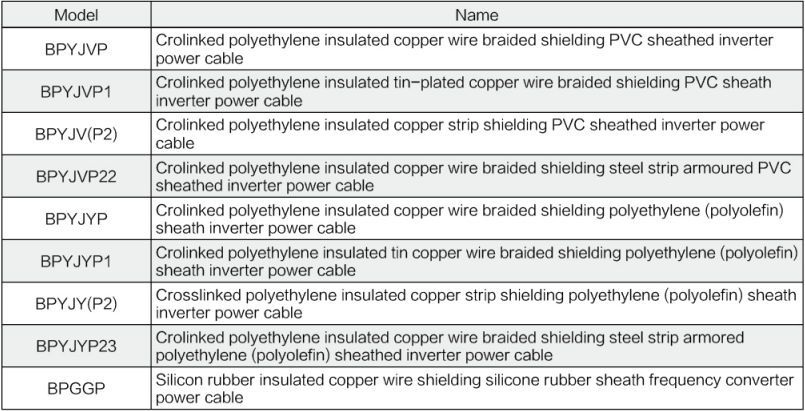

Type & Model

Specifications

Rated Voltage

The rated voltage of the cable is 0.6/1 (1.2) kV and 1.8/3 (3.6) kV.

Execution Standards

Q / RYDL 011-2020 Power cable for rated voltage from 1kV to 3kV.

Material Description

Conductor material: copper wire, copper wire;

Insulation materials: cross-linked polyethylene insulation, polyvinyl chloride insulation, ethylene propylene rubber / elastomer insulation, silicone rubber, polyethylene insulation, polyolefin insulation; Filling materials: PP rope, glass fiber rope; Shield layer: soft copper strip;

Lining layer: PPD embossing belt, PP belt, non-woven fabric, glass fiber band;

Isolation sleeve: polyvinyl chloride, polyethylene, polyolefin, silicone rubber, ethylene propylene rubber / elastomer;

Metal armor: galvanized steel strip, non-magnetic metal tape, galvanized steel wire, non-magnetic wire; Sheath: polyvinyl chloride, polyethylene, polyolefin, silicone rubber, ethylene propylene rubber / elastomer.

Technical parameters

① Conductor temperature during short circuit: cable short circuit allowable maximum temperature (maximum time5S): silicone rubber cable 350℃ , ethylene propylene rubber, crosslinked polyethylene insulated cable250℃,PVC insulated cable160℃ ;

② Conductor working temperature: silicone rubber 180℃ , ethylene propylene rubber, cross-linked polyethylene insulated cable 90℃ , PVC insulated cable 70℃ ;

③Minimum bending radius: Single core: unarmored cable 20D, armored cable 15D; Multi-core: unarmored cable 15D, armored cable 12D; (D is the outer diameter of the cable);

④ Power frequency withstand voltage time and voltage: the power frequency voltage test is 0.6/1kV 3.5kV 5/ min; 1.8/3kV 6.5kV/5min

Company profile

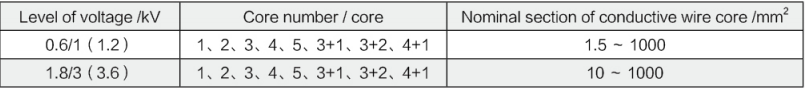

Production process

Applications

Product packaging

Our Services

1. Quickly and professional response.

2. China manufacturer with 8 years experience.

3. Excellent quality with reasonable price.

4. Sufficient support for our tendering representatives.

5. OEM service available based on official & legal authorization.

6. Strict quality control system.

7. Faster lead time than our competitors.

8. Cable solutions to your particular requirements.

9. Free sample is available with economic express fee.

10. 12 months quality guarantee after delivery.

Served Customers

FAQ

Q1: What kind of guarantee do you provide?

A1: 1. 100% high quality, all failed parts get free warranty within 30 days after received.

2. Accept 10 years warranty upon customer requirement.

3. Repairs parts are available within 10years; We will inform the EOL products to you from time to time.

Q2: What if the cable which we need have some differences on specifications from yours?

A2: Any difference, we can design and produce according to your requests, which include cable, color, material, processing requirement etc.

Q3: How can I get a sample to check your quality?

A3: After price confirmation, you can require for sample to check our quality. Sample is free, but the freight charge should be paid.