The Invisible Link: A Guide to Cable Splicing Connectors

2025-12-17 16:49In the vast networks of power distribution, telecommunications, and data transmission, cables must often be joined end-to-end. Whether extending a run, repairing a fault, or branching a circuit, a simple twist of wires is never enough. This is where cable splicing connectors come in. These specialized components are engineered to create a permanent, reliable, and often insulated union between two or more conductors. Far from being a mere mechanical link, a proper splice restores or maintains the cable's electrical continuity, mechanical strength, and environmental protection, forming an "invisible" link that is as robust as the cable itself. The choice of splicing method is critical to the long-term safety and performance of the entire system.

Types and Methods: From Heat to Compression

Splicing connectors are categorized by their installation method and material, each suited to specific cable types and environments.

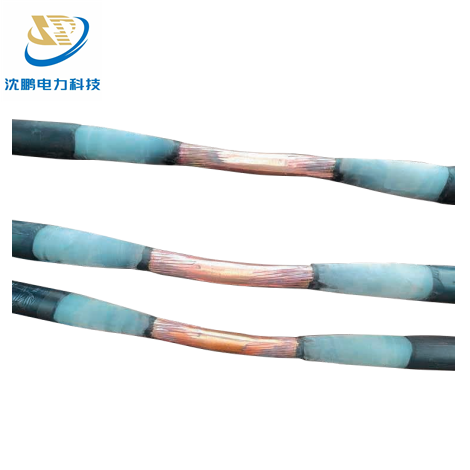

Heat-Shrink Splices: These connectors have a solder or conductive sleeve inside a tube of thermoplastic that is irradiated to shrink when heated. Using a propane torch or heat gun, the installer melts the internal solder (if present) and causes the outer sleeve to shrink tightly around the cable, forming a waterproof, insulated seal. They are widely used for medium-voltage power and telecommunications cables.

Cold-Shrink Splices: These utilize a pre-expanded rubber or elastomeric sleeve held on a removable plastic core. When the core is pulled out, the sleeve contracts radially onto the cable, creating a consistent, high-pressure seal without heat. Ideal for field installations where open flames are hazardous, such as in mining or petrochemical plants.

Mechanical/Compression Splices: These rely on physical force to make the connection. They typically consist of a metal connector (e.g., a copper sleeve) that is crimped or compressed onto the prepared conductors using a dedicated hydraulic or manual tool. They are the standard for low-voltage power, automotive, and grounding applications due to their strength and reliability.

Insulation-Piercing Connectors (IPCs): These allow for a tap or branch connection without stripping the insulation from the main conductor. Sharp, conductive teeth pierce the insulation when the connector is tightened, making contact with the conductor beneath. Common for secondary distribution and service drops on overhead lines.

The Splicing Imperative: Key Advantages

Why go through the trouble of splicing? The benefits are fundamental to system integrity:

Restored Continuity & Low Resistance: A proper splice creates a low-resistance electrical path, minimizing voltage drop and heat generation at the joint—a common failure point in poor connections.

Mechanical Strength: High-quality splices can meet or exceed the tensile strength of the original cable, preventing pull-out under tension.

Environmental Sealing: Most splice kits provide a complete seal against moisture, dust, and chemicals, preventing corrosion and insulation degradation that leads to long-term failure.

Electrical Stress Control: For medium and high-voltage cables, specialized splice kits include conductive and semi-conductive layers to precisely control the electric field at the termination of the cable shield, preventing destructive partial discharges.

Challenges and Considerations: The Price of a Poor Splice

A failed splice is a major point of vulnerability. Key challenges and risks include:

Installation Skill Dependency: The quality of the splice is almost entirely dependent on the installer's technique, training, and use of the correct tools. It is not a "foolproof" process.

Increased Failure Risk: A poorly executed splice is a primary source of future faults—overheating, short circuits, or ground faults—which can be difficult and costly to locate.

Cost and Time: High-quality splice kits and the labor for proper installation represent a significant investment compared to the cable itself. Rushing the process is a false economy.

Point of Inflexibility: The splice point is often the least flexible part of a cable run, which must be considered during installation in trays or conduits.

Where They Are Essential: Primary Application Scenarios

Splicing connectors are indispensable across industries:

Power Utility Networks: For joining and repairing underground medium and high-voltage distribution cables, creating service taps, and connecting overhead lines.

Telecommunications & Fiber Optics: Fusion splicing (melting fibers together) is the standard for low-loss fiber joins, while mechanical splices are used for quick repairs. Copper telecom lines use various insulated connectors.

Industrial Plant Maintenance: For repairing motor leads, extending control cables, and branching circuits within control panels or on factory floors.

Renewable Energy Farms: Interconnecting long runs of cables in solar and wind farms, both for power collection and data/control signals.

Construction and Infrastructure: For creating permanent joints in site wiring, traffic signal systems, and street lighting networks.

The cable splicing connector embodies a critical engineering principle: the whole system is only as strong as its weakest link. These components transform a potential weak point into a node of strength. Selecting the right type—be it heat-shrink for a buried power cable, a cold-shrink for a hazardous location, or a compression lug for a control panel—and ensuring its flawless installation are non-negotiable aspects of professional electrical work. In the hidden architecture of our connected world, the humble splice stands as a testament to the art and science of building reliability, one connection at a time.