Electrical Tapes: A Practical Guide to Types and Applications

2025-09-24 17:12Electrical tape is an indispensable tool for electricians, engineers, and DIY enthusiasts alike. Serving as a versatile solution for insulation, protection, and identification, it plays a critical role in ensuring electrical safety and system reliability.

1. Common Types of Electrical Tapes

PVC (Polyvinyl Chloride) Electrical Tape

This is the most widely used electrical tape, recognizable by its distinctive vinyl stretchiness. PVC tape offers excellent insulation properties, weather resistance, and durability. Its flexibility allows it to conform neatly to wires and connections, creating a tight seal. It is typically available in multiple colors for phase identification.

Rubber Self-Amalgamating Tape

Unlike standard adhesive tapes, this type has no sticky backing. When stretched and wrapped, it bonds to itself, fusing into a seamless, rubber-like layer. This creates a permanent, waterproof seal, making it ideal for moisture-prone environments and cable splicing.

Fiberglass Cloth Tape

Known for its exceptional heat resistance and mechanical strength, this tape can withstand very high temperatures. It is commonly used to bundle and protect cables in hot environments, such as near engines or heating systems.

2. Special-Purpose Tapes

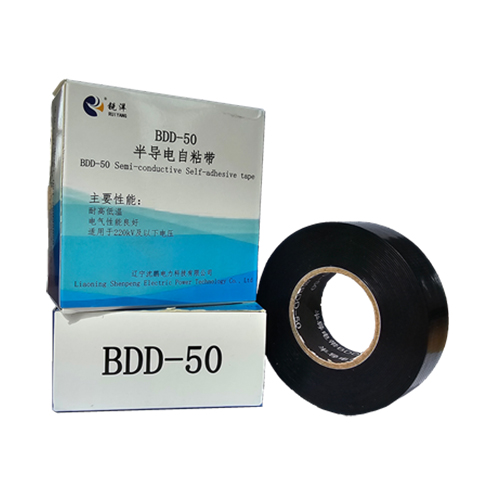

Semi-Conductive Tape: Used in medium and high-voltage cable accessories to control electrical stress.

Shielding Tape: Made from conductive materials like copper or aluminum foil, it provides electromagnetic interference (EMI) shielding.

Phasing Tape: Colored tapes (often green, yellow, red, blue) used to identify different voltage phases and neutral wires in electrical panels and cables.

3. Primary Applications

Electrical Insulation

The fundamental use of electrical tape is to provide an insulating barrier. It is used to insulate splices in electrical wires, cover exposed conductors, and repair minor damage to cable jackets, preventing short circuits and electrical shocks.

Environmental Sealing and Protection

Tapes like rubber self-amalgamating tape are crucial for creating waterproof and dustproof seals in cable joints and terminations, especially for underground or outdoor installations. They protect connections from moisture, corrosion, and contaminants.

Cable Bundling and Harnessing

Tapes are used to neatly bundle loose wires and cables together, which improves organization, reduces strain on individual wires, and minimizes the risk of tangling or damage within control panels or machinery.

Identification and Marking

Color-coded tapes are a simple and effective method for identifying circuit functions, voltage levels, or phases, which is essential for safety, maintenance, and troubleshooting.

4. How to Choose the Right Tape?

Selecting the appropriate tape depends on the specific task:

For general-purpose insulation on household wires: Standard PVC Electrical Tape is sufficient.

For waterproof sealing on outdoor cable splices: Choose Rubber Self-Amalgamating Tape.

For high-temperature environments: Fiberglass Cloth Tape is the best option.

For identifying circuits: Use colored Phasing Tape.

In summary, understanding the properties and correct applications of different electrical tapes is key to performing safe and durable electrical work. Always ensure the tape is certified to relevant safety standards (like UL or IEC) for your specific application.