Dry Type GIS (Plug-in) Termination

ODM & OEM: Yes

Transport Package: Wooden case

Used in electric transmission and distribution system operation

Strict quality control system

- Shenpeng

- Shenyang, China

- 15 working days after payment is received

- 1.5 days per set (low & medium voltage); 2 days per set (high voltage)

- Information

- Download

Dry Type GIS (Plug-in) Termination

Product Description

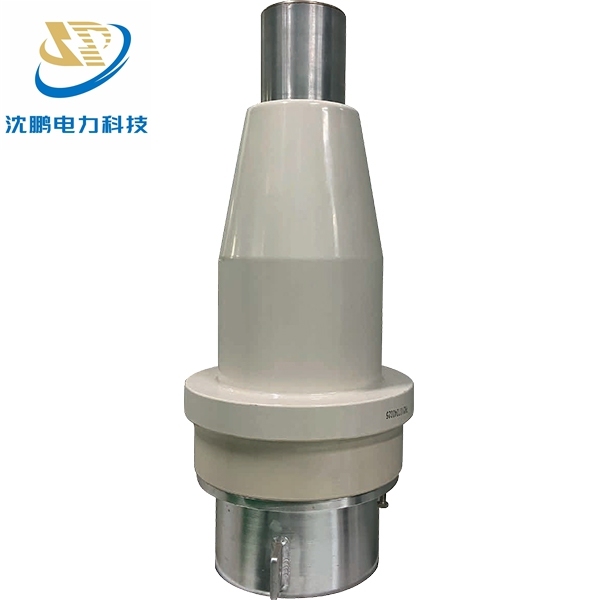

The Dry Type GIS (Plug-in) Termination represents a cutting-edge solution for connecting high-voltage power cables directly to Gas Insulated Switchgear (GIS) in a safe, efficient, and maintenance-free manner. Unlike traditional terminations that require insulating fluids or gels, this "dry" design utilizes pre-molded, engineered polymer components such as silicone rubber with integrated electrical stress control layers. Its plug-in configuration allows for seamless and tool-less installation into standardized GIS bushings, significantly reducing commissioning time and labor costs while eliminating the risk of leakage or contamination associated with liquid-filled systems. This termination type ensures exceptional dielectric performance, reliability, and compatibility with SF6 or alternative eco-friendly insulating gases within the GIS environment.

Its lightweight and modular design simplifies transportation and handling, while its partial discharge-free performance enhances the longevity of both the cable and GIS equipment. The Dry Type GIS Plug-in Termination is designed for voltage ratings from 72.5kV to 550kV, providing a sustainable and future-proof solution for modern power transmission and distribution systems.

Design Methods

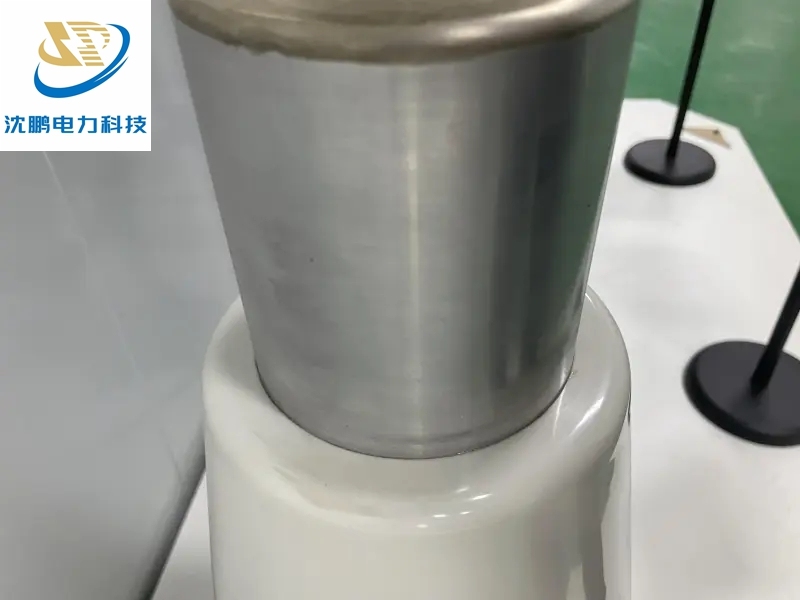

GIS Termination consists of two parts: the expoxy sleeve and the plug.The expoxy sleeve can be sent to the GIS manufacture for pre-installation. Repair or maintenance of equipment or cable runs can be performed without breaking the seal between the epoxy sleeve and the equipment.

Silicone rubber stress cones provide electrical stress cones stress control.

Connectors with multi-point contact springs are used to pr ovide

A metal spring pressure device ensures that the stress cone is always tight against the inside wall of the epoxy sleeve that it is shaped to fit and ensures interface pressure.

The cable fixing and sealing device at the termination will be connected to the outer sheath of the cable, acting as a fixing and mechanical protection and providing a separate earth connection with No welding.

In the event that it is necessary to replace an old oil-filled terminal in a transformer or oil -filled insulated switchgear, the termination outlets can be matched by means of optional extension rods and fixing rings.

Feature

Dry interface, no oil filling required

Dimensions: Available according to IEC62271-209,Different sizes of epoxy sleeves are available according to IEC62271-209, GB/T22381, IEC60859.

Can be operated in SF6 or insulating oil environments.

Prefabricated silicone rubber stress cones,100% factory inspected.

Terminations can be installed without special tools or brazing.

Bottom flange and termination can be grounded separately.

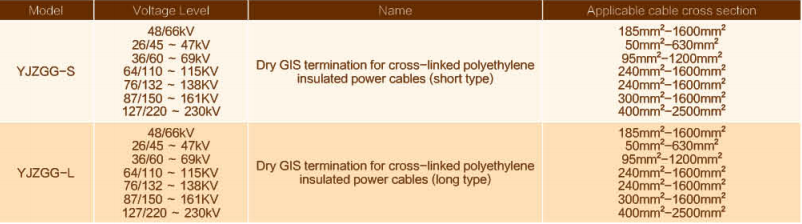

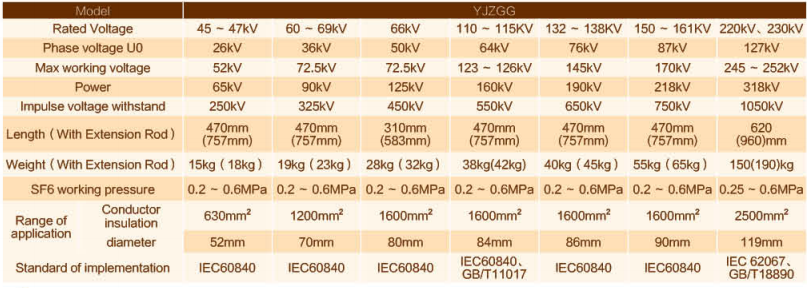

Technical Parameter

Product Dimension