Dry Y-Intermediate Joint

Transport Package: Carton

Designed for creating branched connections in medium-voltage power cable systems

Strict quality control system

- Shenpeng

- Shenyang, China

- 15 working days after payment is received

- 1.5 days per set

- Information

- Download

Dry Y-Intermediate Joint

Product Description

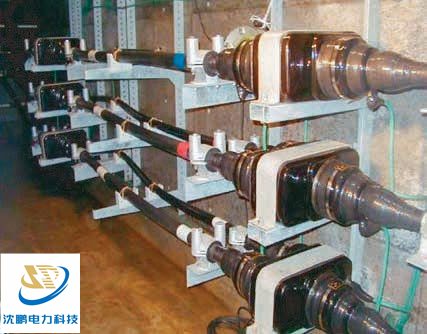

The Dry Y-Intermediate Joint is an innovative and maintenance-free solution designed for creating branched connections in medium-voltage power cable systems without requiring insulating fluids or gels. Utilizing advanced dry technology, this joint features a modular design with pre-molded silicone rubber components that integrate stress control layers and sealing interfaces. Its unique Y-configuration allows a single incoming cable to split into two independent outgoing circuits, enabling flexible power distribution while maintaining electrical integrity and mechanical protection. The joint ensures uniform electric field distribution across all branching points, preventing partial discharge and minimizing energy losses. Ideal for underground networks, industrial complexes, and renewable energy farms, this solution eliminates the need for messy compounds or heat application, reducing installation time and environmental risks.

Engineered for durability and adaptability, the Dry Y-Intermediate Joint employs cold-shrink or push-fit technology for tool-free installation, ensuring a tight, waterproof seal even in challenging environments. The high-grade silicone rubber construction offers excellent resistance to moisture, UV radiation, temperature extremes (-50°C to +50°C), and chemical corrosion, guaranteeing long-term performance in direct burial, trench, or tunnel applications. This joint is compatible with XLPE-insulated cables and supports seamless integration into existing grid infrastructure. Its lightweight yet robust design simplifies handling and reduces overall system complexity, making it a preferred choice for utility upgrades, substation expansions, and distributed energy projects.

Design Methods

The joint body is cast in epoxy resin, and the three-phase dry plug-in terminals are connected to the body to complete the Y-connection of the line.

Adoption of compact design of spring pressure stress cone design, short cable stripping distance, shorter preparation time, and the whole joint installation time and staffing are the same as ordinary joints.

Adoption of prefabricated body, users can choose to run the main line after plugging the branch line portion with a plug(separately required). If necessary, the plug can be removed and the branch line inserted.If necessary, the plug can be removed and the branch line can be inserted for operation.

Since the grounding of the three phases , the connector is not connected to each other, the other two phases are allowed to continue to operate after a fault in one of the phases off the line.

Feature

Fully dry, reduced Y-joint, small size.

Use of cross sections from 240 mm2 to 1600 mm².

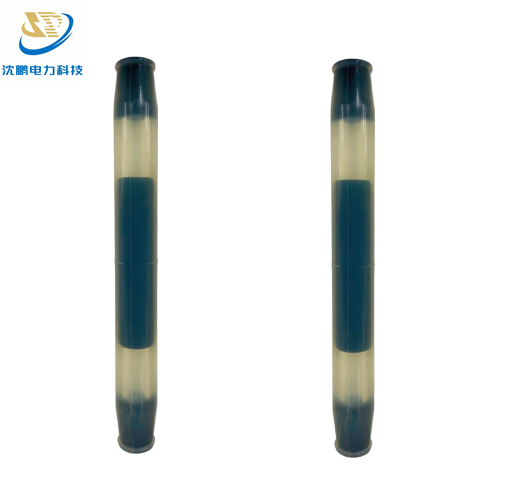

Prefabricated stress cone structure.

Plug-in design for easy testing and operational requirements,One-piece cast epoxy body with copper shell encapsulated in body and insulating material cover the body.

The metal layer is separated from the body to provide a variety of grounding options.

Stress cone plugs, single line operation option available.

Optional cast protective housing Underwater operation is permitted, taking into account the possibility of water ingress into the coupling's operating environment, the product has been designed and tested to withstand 1 meter of water pressure.

The insulation sleeve of each phase and the shielding layer between the cables are insulated, making the measurement of insulation resistance,etc.during periodic inspections reliable and easy.

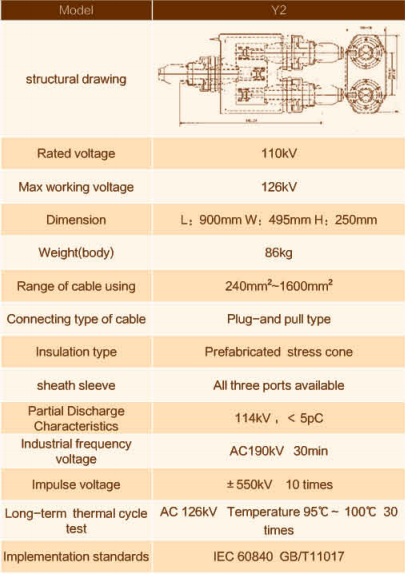

Technical Parameter