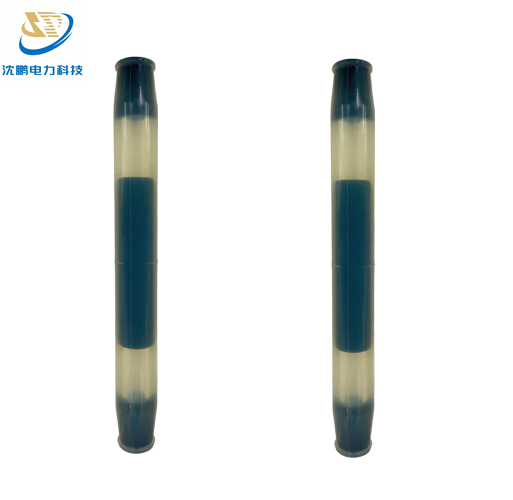

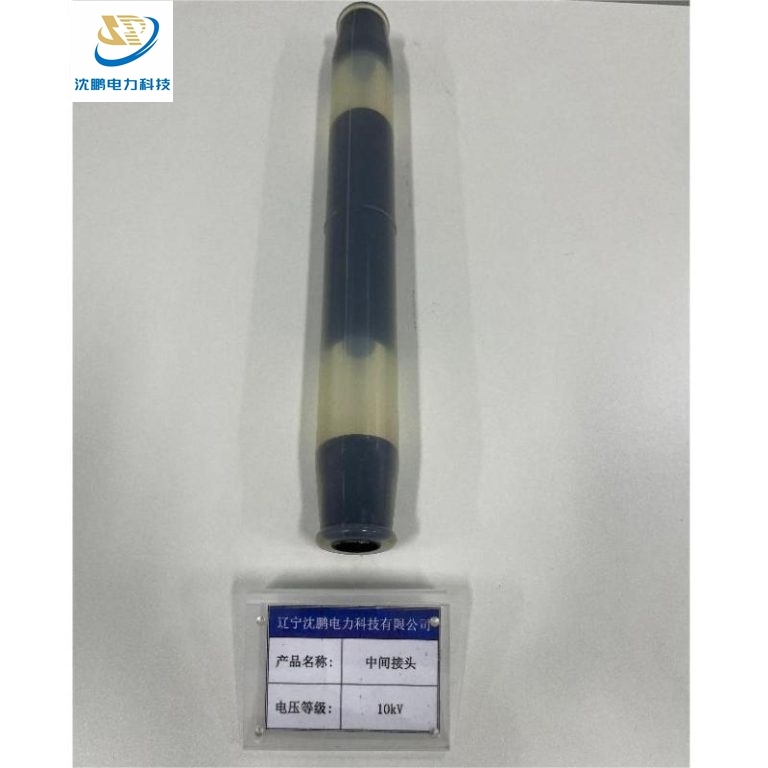

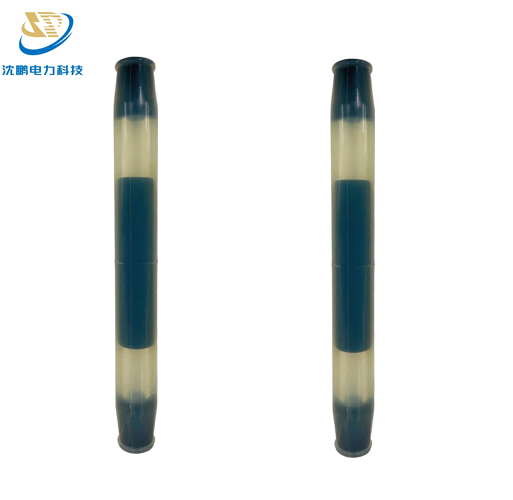

10kV Cold Shrink Intermediate Joint

Transport Package: Carton

Designed to seamlessly connect two separate cable segments

Strict quality control system

- Shenpeng

- Shenyang, China

- 15 working days after payment is received

- 1.5 days per set

- Information

- Download

10kV Cold Shrink Intermediate Joint

Product Description

The 10kV Cold Shrink Intermediate Joint delivers significant operational advantages through its maintenance-free design and rapid deployment capability. By eliminating the need for hot work permits and specialized installation equipment, it reduces project timelines and labor costs by up to 60% compared to traditional solutions. The joint's predictable, repeatable installation process ensures consistent performance regardless of crew experience level, while its durable construction guarantees decades of reliable service without requiring inspection or maintenance interventions.

This advanced splicing solution represents the optimal balance of technical excellence and economic efficiency, providing network operators with a future-proof asset that enhances system reliability while reducing total cost of ownership. Its robust design philosophy and proven performance characteristics make it the intelligent choice for engineers seeking to build resilient, long-lasting power infrastructure.

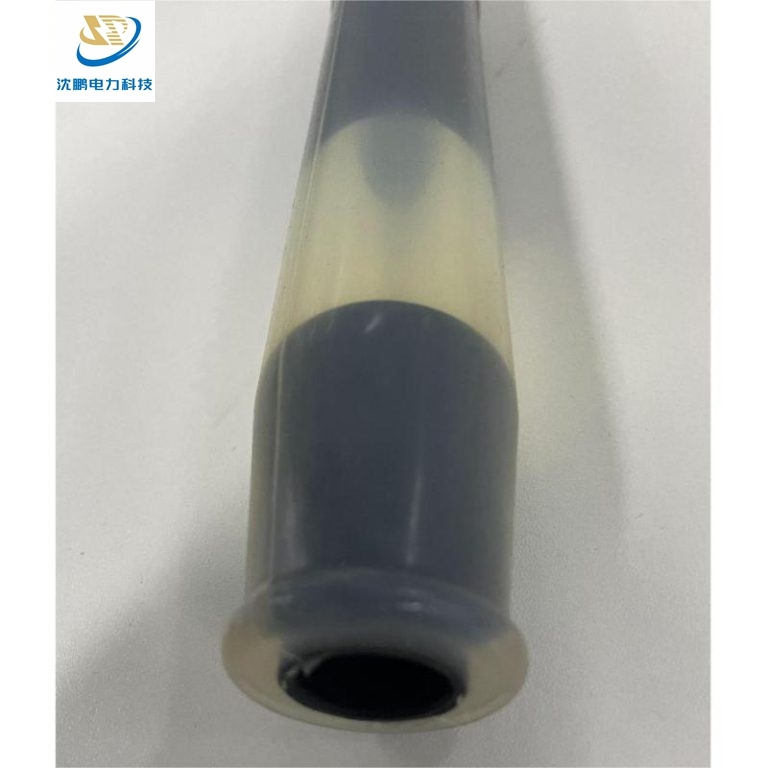

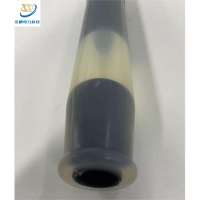

At the heart of its performance lies an innovative Geometric Field Control (GFC) system, featuring seamlessly integrated semi-conductive and insulating layers that work in harmony to eliminate electrical stress concentrations. This advanced field grading technology ensures optimal electric field distribution across the entire splice region, effectively preventing corona formation and partial discharge activity even under continuous full-load conditions. The joint's proprietary material composition maintains stable dielectric properties throughout its operational life, providing consistent protection against electrical aging and insulation breakdown.

The joint's environmental resilience stems from its specially formulated hybrid polymer compound, which combines the best properties of silicone rubber and advanced elastomers. This unique material synergy delivers exceptional performance in challenging conditions, including:

Complete immunity to UV degradation and ozone exposure

Superior hydrophobic characteristics preventing water tracking

Chemical resistance to oils, solvents, and acidic/alkaline environments

Wide temperature tolerance from -50°C to +50°C with maintained flexibility

Excellent mechanical strength to withstand soil pressures and vibration stresses

Design Methods

This product is made of liquid silicone rubber, compared with solid silicone rubber elasticity is better, better reliability Waterproof shell is made of fiberglass, waterproof glue AB components

The shielding lap is made of twisted copper mesh and copper braid and has passed the shielding short-circuit test. The factory withstand voltage test 39kV, 5min

The product implements is the national standard GB/T12706.4.

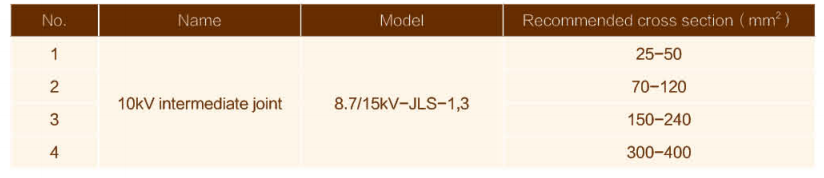

Technical Parameter

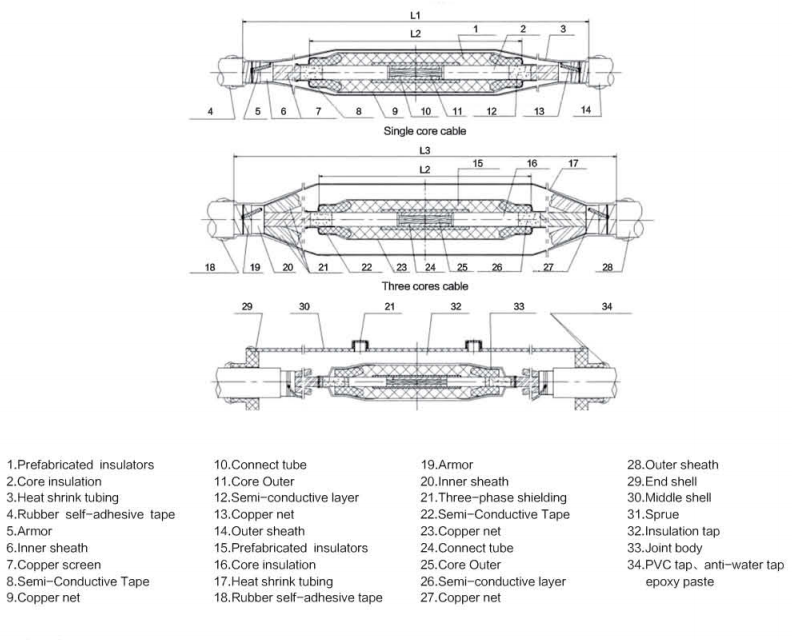

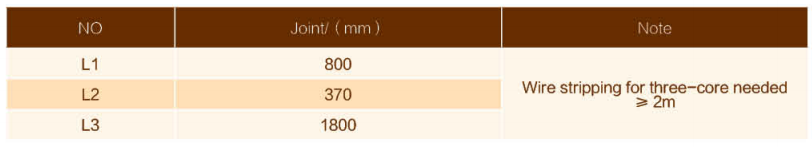

Product Dimension