Integral Prefabricated (Dry) Cable Termination

ODM & OEM: Yes

Transport Package: Wooden case

Used in electric transmission and distribution system operation

Strict quality control system

- Shenpeng

- Shenyang, China

- 15 working days after payment is received

- 1.5 days per set (low & medium voltage); 2 days per set (high voltage)

- Information

- Download

Integral Prefabricated (Dry) Cable Termination

Product Description

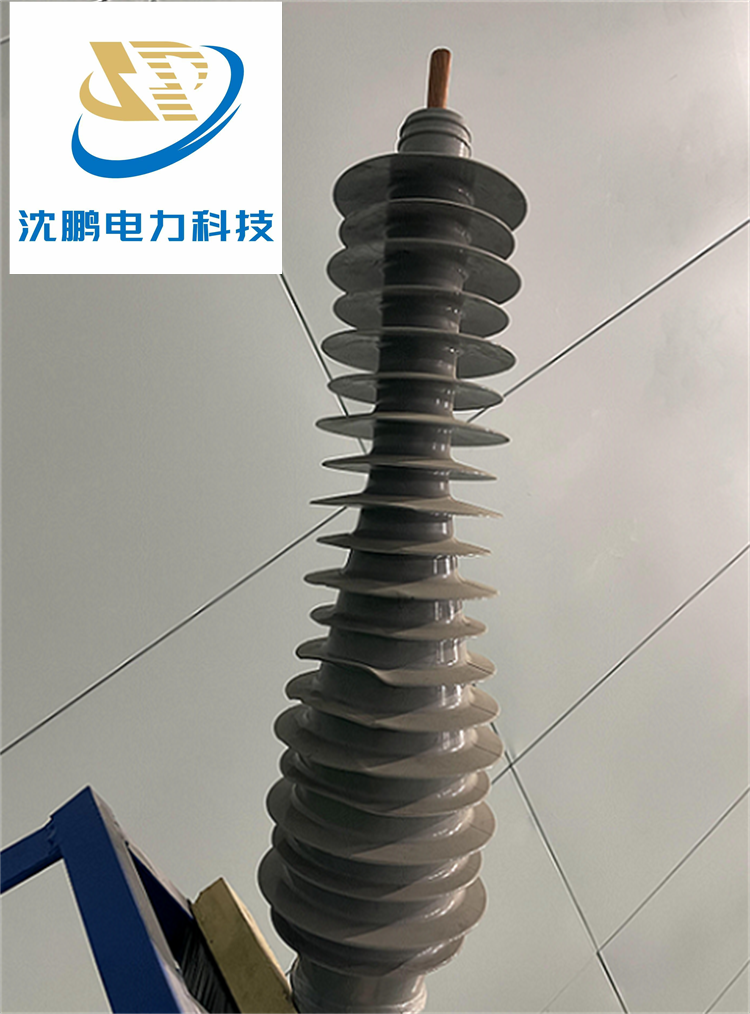

The Integral Prefabricated (Dry) Cable Termination is a modern, engineered solution designed to simplify and accelerate the installation of medium and high-voltage cable systems while ensuring superior reliability. Unlike traditional termination methods that require field-assembled components and liquid/gel fillers, this termination features a factory-assembled, single-unit design with pre-installed dielectric stress control elements and silicone rubber insulation. Its "dry" construction eliminates the need for on-site pouring, heating, or specialized handling of insulating compounds, significantly reducing installation time and the risk of human error. The termination provides a complete, sealed interface for connecting cables to switchgear, transformers, or overhead lines, offering consistent performance and enhanced safety.

Ideal for utility, industrial, and commercial applications, this termination type excels in environments where speed, cleanliness, and reliability are critical. Its lightweight and compact design reduces space requirements in substations and switchrooms, while the silicone rubber housing delivers excellent resistance to UV radiation, pollution, moisture, and temperature fluctuations. The Integral Prefabricated Dry Termination is available for voltage ratings from 10kV to 66kV, providing a maintenance-free solution for power distribution networks, renewable energy plants, and data centers.

Design Methods

Integral prefabricated terminations are made of imported liquid silicone rubber, and the stress cone and silicone rubber insulation are prefabricated into a whole.

It has good weather resistance,resistance to leakage traces, and excellent antifouling performance.

Dry terminations do not contain filled insulating oil, so there is a lot of freedom of installation, and the installation position and direction can be changed flexibly according to the needs of the site, it can be installed vertically or at an angle.

The product is made of silicone rubber, which is light in weight and has good anti-explosion and anti-vibration properties. At the same time, the installation of low support requirements, especially suitable for high towers and not convenient for lifting machinery to enter the region.

Feature

Prefabrication of stress cones, insulators, and sheds molds in a clean room at the factory.

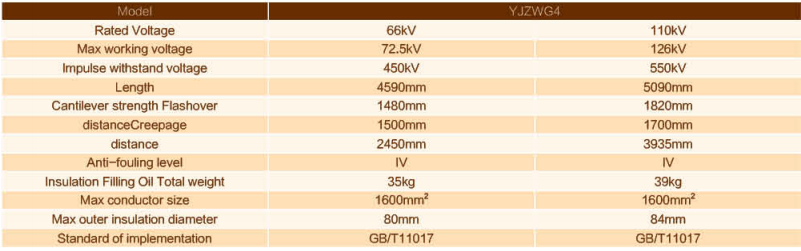

100% testing of partial discharge of cable accessories, no partial discharge under test voltage. High quality stability and reliability Silicone rubber prefabricated stress cone Class IV, 4590mm, (36mm/kV) Light weight <35kg.

Easy and quick installation.

Dry type,without any insulant,maintenance- free.

Special non-welded combined grounding process, ensuring no damage to cables.

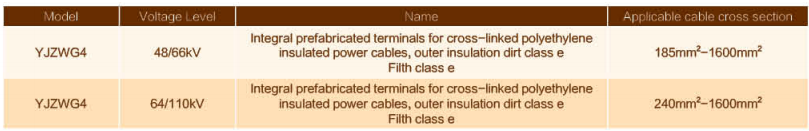

Technical Parameter

Product Dimension