Composite Sleeve Termination

ODM & OEM: Yes

Transport Package: Wooden case

Used in electric transmission and distribution system operation

Strict quality control system

- Shenpeng

- Shenyang, China

- 15 working days after payment is received

- 1.5 days per set (low & medium voltage); 2 days per set (high voltage)

- Information

- Download

Composite Sleeve Termination

Product Description

The Composite Sleeve Termination is an advanced outdoor cable termination solution designed for medium and high-voltage power systems. It replaces traditional porcelain insulators with a lightweight, polymer-hybrid composite sleeve that combines exceptional mechanical strength with excellent electrical performance. The design typically integrates silicone rubber sheds for superior hydrophobicity, UV resistance, and pollution resistance, ensuring reliable operation in harsh environmental conditions. This termination type is engineered to provide a seamless interface between the cable and overhead line or transformer connection, effectively managing electrical stress and preventing partial discharge.

Ideal for substations, industrial plants, and renewable energy facilities, the Composite Sleeve Termination offers significant advantages over conventional solutions. Its lightweight nature simplifies installation and reduces structural support requirements, while its fracture-resistant design enhances safety by eliminating the risk of explosive failure associated with porcelain. This termination is widely used in applications ranging from 10kV to 500kV systems, providing long-term durability and minimal maintenance needs.

Design Methods

Pressure-sealed composite insulating sleeves are made of fiberglass reinforced sleeves with extruded silicone rubber sheds molds on the outer layer. The upper end cap and chassis are made of corrosion-resistant alloy material. The metal fitting associated with the termination consists of corrosion-presistant alloy.

Mechanical take-offs for torque-controlled break-off bolts are connected to the cable conductors and sealed with oil-resistant filler rubber and heat-shrink tubing. Silicone rubber stress cones provide electrical stress control.

Insulating oil is used to fill between the stress cone and the inner wall of the cable and composite sleeve. Different cable fixing and sealing devices are used for different cable sheath and construction.

Support insulators are provided for separate earthing and cross interconnection.

Feature

Pressure-tight and light weight composite housing.

Lightweight pressure-sealed.

Prefabricated and factory test silicone rubber stress cone.

Higher crimping strength of outgoing line rod Sealed with heat shrinkable tube No special tools required to instant.

Fill the insulating oil at atmospheric pressure(can be injected from the top of Termination ) Independent insulating base.

Fittings are made of corrosion-resistant alloy material.

Test according to IEC 60840 & IEC 62067 standards.

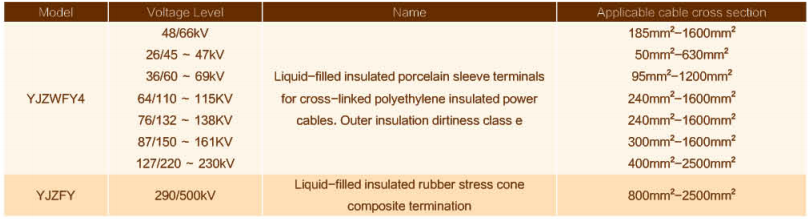

Technical Parameter

Product Dimension