- Home

- >

- Products

- >

- Intermediate Joint

- >

Intermediate Joint

Transport Package: Carton

Designed to seamlessly connect two separate cable segments

Strict quality control system

- Shenpeng

- Shenyang, China

- 15 working days after payment is received

- 100 sets per month

- Information

- Download

Intermediate Joint

Product Description

The Intermediate Joint is a critical component in power cable systems, designed to seamlessly connect two separate cable segments while restoring electrical, mechanical, and environmental integrity. Engineered for durability and reliability, it ensures uninterrupted power transmission by maintaining consistent electrical parameters such as impedance and voltage stress distribution across the joint. Utilizing advanced materials like triple-layered silicone rubber with integrated stress control components, the joint effectively manages electrical field gradients and prevents partial discharge. Its construction accommodates thermal expansion, mechanical vibrations, and environmental challenges, making it suitable for direct burial, underground ducts, or tunnel installations in utilities, industrial complexes, and renewable energy networks.

The joint provides waterproofing, corrosion resistance, and long-term stability even in harsh conditions like high humidity, chemical exposure, or temperature extremes (-50°C to +50°C).

Design Methods

High reliability, quick and easy installation, realizing the simplicity of on-site installation process.

Prefabricated rubber coupling includes stress cone, high- pressure shielding tube and outer thick-walled tube, which are injected and pressed into one piece; the use of high- quality silicone rubber ensures excellent electrical reliability and mechanical properties.

Long stress cone and high pressure shielding tube improves the problem of stress concentration and prolongs the product life.

Screwed mechanical or compression tubing ensures good mechanical and electrical properties.

Cold connection (solderless) grounding avoids heat generated during the soldering process that could cause damage to the cable.

Feature

Prefabrication of stress cones, insulators, and sheds molds in a clean room at the factory.

100% testing of partial discharge of cable accessories, no partial discharge under test voltage.

High quality stability and reliability.

Silicone rubber prefabricated stress cones.

Highly dirt-proof, Class IV, 4590mm, (36mm/ kV).

Light weight <35kg.

Easy and quick installation.

Dry type, without any insulant, maintenance-free Special non-welded combined grounding process, ensuring no risk of damage to cable insulation. Can be installed in any position. Voltage level: 66kV-110kV.

Applicable cross section 185mm2-1600mm2. Designed and tested according to GB11017.

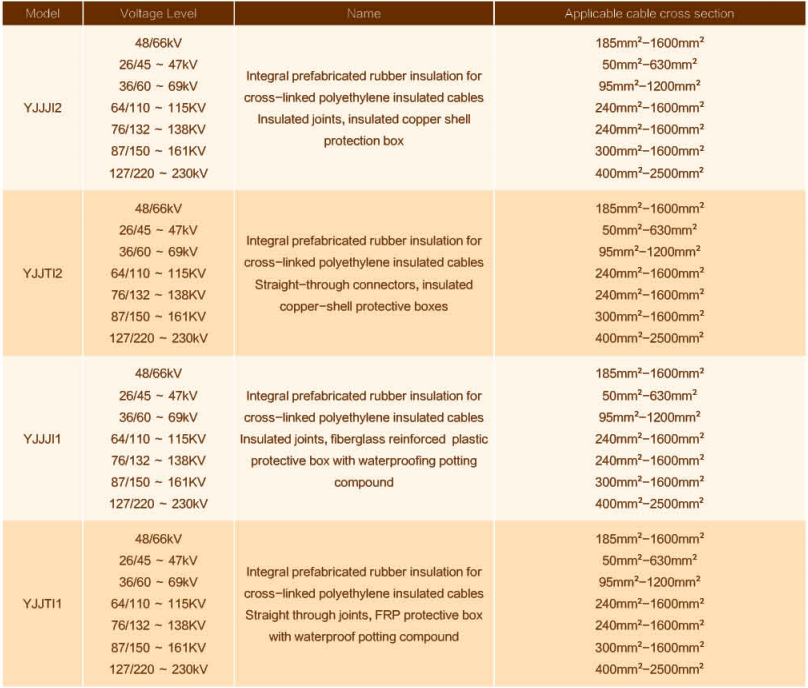

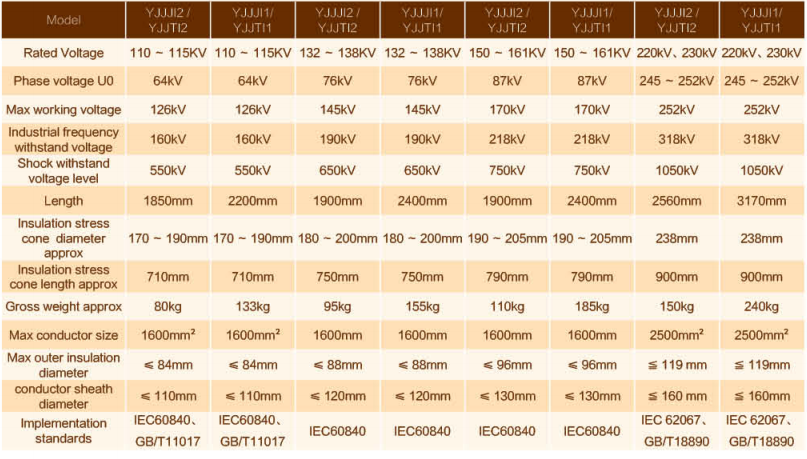

Technical Parameter

Product Dimension