Porcelain Sleeve Termination

ODM & OEM: Yes

Transport Package: Wooden case

Used in electric transmission and distribution system operation

Strict quality control system

- Shenpeng

- Shenyang, China

- 15 working days after payment is received

- 1.5 days per set (low & medium voltage); 2 days per set (high voltage)

- Information

- Download

Porcelain Sleeve Termination

Product Description

The Porcelain Sleeve Termination is a classic and reliable outdoor termination solution for medium and high-voltage cable systems, leveraging decades of proven performance in electrical infrastructure. Constructed with high-strength electroporcelain, this termination features a glazed ceramic sleeve that provides exceptional mechanical durability, resistance to environmental degradation, and stable dielectric properties under varying weather conditions. Its design effectively controls electrical stress at the cable-end interface, preventing corona discharge and ensuring safe connection to overhead lines or transformers. The porcelain's inherent resistance to UV radiation, temperature extremes, and pollution makes it suitable for long-term operation in industrial and utility environments.

Widely used in substations, power distribution networks, and industrial facilities, this termination type offers compatibility with traditional grid infrastructure and rigorous operational requirements. While heavier than polymer alternatives, porcelain sleeves provide unmatched compressive strength and fire resistance, maintaining functionality even in high-fault conditions. The porcelain terminations are available for voltage classes from 10kV to 550kV, serving as a robust choice for applications where tradition, reliability, and extended service life are prioritized.

Design Methods

The porcelain sleeve for the pressure seal is made of brown high-strength porcelain. The upper end cap and the chassis are made of a corrosion-resistant alloy.

Mechanical connectors for the torque control breaker bolts are connected to the cable conductor and sealed with oil- resistant filler and heat shrink tubing.

Silicone rubber stress cones provide electrical stress control. Insulating oil is used to fill the gap between the stress cone and the inner wall of the cable and the ceramic sleeve.

Different cable fixing and sealing devices are used depending on the cable sheath and armoring configuration.

Support insulators are provided for separate earthing and cross interconnection.

Feature

Light weight pressure-sealed porcelain sleeve.

Prefabricated and factory-tested silicone rubber stress cones.

Torque-controlled mechanical tubing Heat-shrink tubing seals.

No special tools required for installation.

Insulation oil filled at atmospheric pressure(can be injected from the top of the terminal).

Separate insulating chassis.

Fittings are made of corrosion-resistant alloy materials.

Test according to IEC60840 & IEC62067 standards.

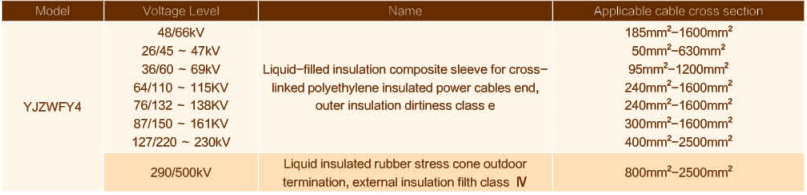

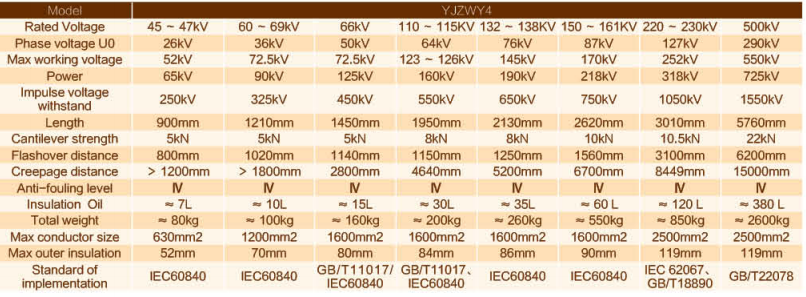

Technical Parameter

Product Dimension