- Home

- >

- Products

- >

- Welding Splice

- >

Welding Splice

Transport Package: Carton

Designed to create a permanent, high-conductivity connection between electrical conductors

Strict quality control system

- Shenpeng

- Shenyang, China

- 15 working days after payment is received

- 100 sets per month

- Information

- Download

Welding Splice

Product Description

The Welding Splice represents the pinnacle of electrical connection technology, delivering a permanent, high-conductivity interface between conductors through advanced metallurgical bonding processes. Unlike conventional mechanical or compression connectors that rely on surface contact pressure, welding splicing creates a homogeneous molecular union between conductor materials—typically copper, aluminum, or their alloys. This is achieved through precisely controlled exothermic reactions (thermite welding) or specialized arc welding techniques that generate sufficient thermal energy to melt and fuse the conductor materials at their interface, forming a seamless metallic continuum that essentially becomes a single, continuous conductor.

The fundamental advantage of this technology lies in its ability to create connections with electrical and mechanical properties that frequently exceed those of the original conductors. The resulting splice exhibits negligible resistance, eliminating the localized heating and potential hot spots common in mechanical connections. This molecular-level fusion ensures exceptional current-carrying capacity and mechanical strength, maintaining integrity under extreme short-circuit conditions, prolonged thermal cycling, and mechanical vibration. The welded joint demonstrates superior resistance to galvanic and electrochemical corrosion, as the fused interface eliminates the microscopic gaps where corrosive elements typically initiate degradation.

Exothermic welding systems, the most prevalent method for field applications, utilize precision-engineered graphite molds and specially formulated welding charges to create consistent, high-quality connections. These pre-packaged kits—containing molds, welding material, igniters, and accessories—enable reliable field deployment with minimal equipment. The process creates a connection whose current-carrying capacity typically exceeds that of the conductor itself, with a melting point higher than copper and exceptional resistance to repeated fault currents.

Design Methods

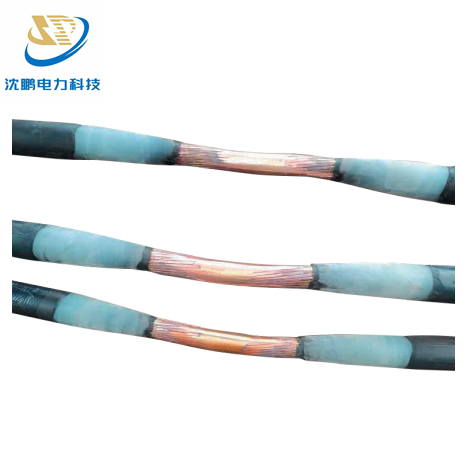

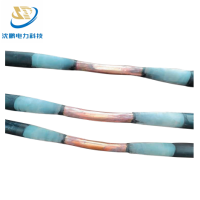

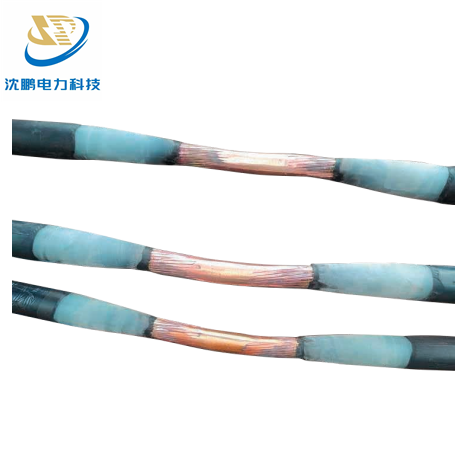

The conductor is melted at high temperature so that the ends of the conductor are fused into one, compared with crimping, there is no change in structural dimensions, higher tensile strength and other advantages. Suitable for 10-35kV cables.

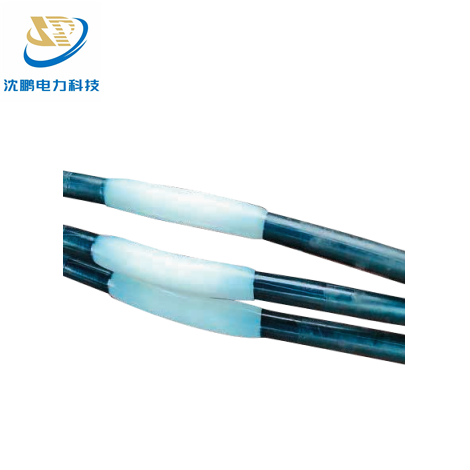

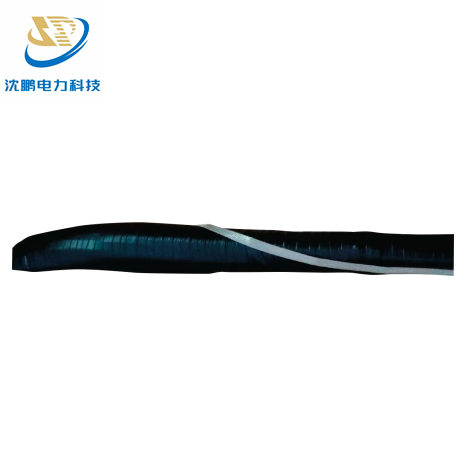

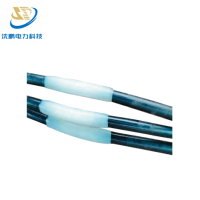

When the splice welding is completed, using the form of winding through high temperature vulcanization in order to restore the cable's inner semiconducting shield, insulation, outer semi conducting shield; metal shielding, steel tape, sheath in accordance with the installation of the ordinary way to restore.

The welding splice can nearly restore the cable size in terms of dimensions and performs better in terms of waterproof performance, which is suitable for environments with relatively harsh conditions of humidity.